Page 13 - Numerical Analysis and Modelling in Geomechanics

P. 13

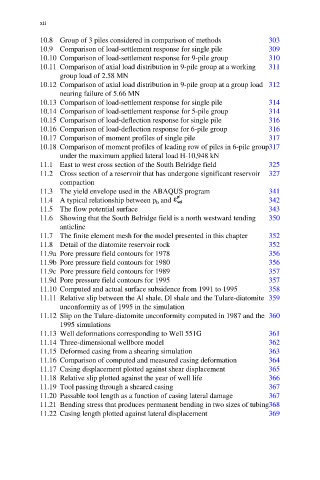

xii

10.8 Group of 3 piles considered in comparison of methods 303

10.9 Comparison of load-settlement response for single pile 309

10.10 Comparison of load-settlement response for 9-pile group 310

10.11 Comparison of axial load distribution in 9-pile group at a working 311

group load of 2.58 MN

10.12 Comparison of axial load distribution in 9-pile group at a group load 312

nearing failure of 5.66 MN

10.13 Comparison of load-settlement response for single pile 314

10.14 Comparison of load-settlement response for 5-pile group 314

10.15 Comparison of load-deflection response for single pile 316

10.16 Comparison of load-deflection response for 6-pile group 316

10.17 Comparison of moment profiles of single pile 317

10.18 Comparison of moment profiles of leading row of piles in 6-pile group 317

under the maximum applied lateral load H-10,948 kN

11.1 East to west cross section of the South Belridge field 325

11.2 Cross section of a reservoir that has undergone significant reservoir 327

compaction

11.3 The yield envelope used in the ABAQUS program 341

11.4 A typical relationship between p and 342

b

11.5 The flow potential surface 343

11.6 Showing that the South Belridge field is a north westward tending 350

anticline

11.7 The finite element mesh for the model presented in this chapter 352

11.8 Detail of the diatomite reservoir rock 352

11.9a Pore pressure field contours for 1978 356

11.9b Pore pressure field contours for 1980 356

11.9c Pore pressure field contours for 1989 357

11.9d Pore pressure field contours for 1995 357

11.10 Computed and actual surface subsidence from 1991 to 1995 358

11.11 Relative slip between the Al shale, Dl shale and the Tulare-diatomite 359

unconformity as of 1995 in the simulation

11.12 Slip on the Tulare-diatomite unconformity computed in 1987 and the 360

1995 simulations

11.13 Well deformations corresponding to Well 551G 361

11.14 Three-dimensional wellbore model 362

11.15 Deformed casing from a shearing simulation 363

11.16 Comparison of computed and measured casing deformation 364

11.17 Casing displacement plotted against shear displacement 365

11.18 Relative slip plotted against the year of well life 366

11.19 Tool passing through a sheared casing 367

11.20 Passable tool length as a function of casing lateral damage 367

11.21 Bending stress that produces permanent bending in two sizes of tubing 368

11.22 Casing length plotted against lateral displacement 369