Page 385 - Numerical Analysis and Modelling in Geomechanics

P. 385

366 RESERVOIR COMPACTION, SUBSIDENCE AND WELL DAMAGE

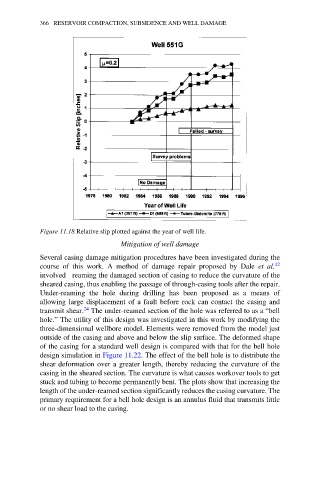

Figure 11.18 Relative slip plotted against the year of well life.

Mitigation of well damage

Several casing damage mitigation procedures have been investigated during the

course of this work. A method of damage repair proposed by Dale et al. 42

involved reaming the damaged section of casing to reduce the curvature of the

sheared casing, thus enabling the passage of through-casing tools after the repair.

Under-reaming the hole during drilling has been proposed as a means of

allowing large displacement of a fault before rock can contact the casing and

24

transmit shear. The under-reamed section of the hole was referred to as a “bell

hole.” The utility of this design was investigated in this work by modifying the

three-dimensional wellbore model. Elements were removed from the model just

outside of the casing and above and below the slip surface. The deformed shape

of the casing for a standard well design is compared with that for the bell hole

design simulation in Figure 11.22. The effect of the bell hole is to distribute the

shear deformation over a greater length, thereby reducing the curvature of the

casing in the sheared section. The curvature is what causes workover tools to get

stuck and tubing to become permanently bent. The plots show that increasing the

length of the under-reamed section significantly reduces the casing curvature. The

primary requirement for a bell hole design is an annulus fluid that transmits little

or no shear load to the casing.