Page 205 - Optofluidics Fundamentals, Devices, and Applications

P. 205

180 Cha pte r Ei g h t

Wave guides

Liquid Add signal Fluid In signal

Bubble Trench

Center heater

Optical

waveguide

Sidewall

metalization

Bubble

Drop signal Out signal

(a) (b)

Mirror channel

Flow channels 2 mm 3 4 5

2

1 2

1

Inlet 1 Inlet 2 Outlet

Laser

beams Control channels

1 Vent 2 3, 4 5

(c) (d)

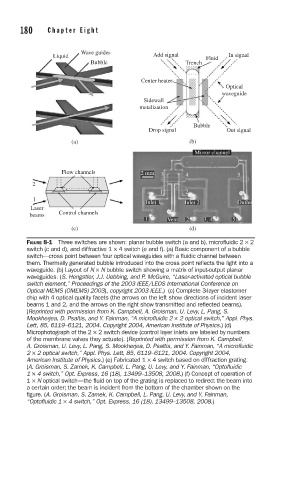

FIGURE 8-1 Three switches are shown: planar bubble switch (a and b), microfl uidic 2 × 2

switch (c and d), and diffractive 1 × 4 switch (e and f). (a) Basic component of a bubble

switch—cross point between four optical waveguides with a fl uidic channel between

them. Thermally generated bubble introduced into the cross point refl ects the light into a

waveguide. (b) Layout of N × N bubble switch showing a matrix of input-output planar

waveguides. (S. Hengstler, J.J. Uebbing, and P. McGuire, “Laser-activated optical bubble

switch element,” Proceedings of the 2003 IEEE/LEOS International Conference on

Optical MEMS (OMEMS) 2003), copyright 2003 IEEE.) (c) Complete 3-layer elastomer

chip with 4 optical quality facets (the arrows on the left show directions of incident laser

beams 1 and 2, and the arrows on the right show transmitted and refl ected beams).

(Reprinted with permission from K. Campbell, A. Groisman, U. Levy, L. Pang, S.

Mookherjea, D. Psaltis, and Y. Fainman, “A microfl uidic 2 × 2 optical switch,” Appl. Phys.

Lett, 85, 6119–6121, 2004. Copyright 2004, American Institute of Physics.) (d)

Microphotograph of the 2 × 2 switch device (control layer inlets are labeled by numbers

of the membrane valves they actuate). (Reprinted with permission from K. Campbell,

A. Groisman, U. Levy, L. Pang, S. Mookherjea, D. Psaltis, and Y. Fainman, “A microfl uidic

2 × 2 optical switch,” Appl. Phys. Lett, 85, 6119–6121, 2004. Copyright 2004,

American Institute of Physics.) (e) Fabricated 1 × 4 switch based on diffraction grating.

(A. Groisman, S. Zamek, K. Campbell, L. Pang, U. Levy, and Y. Fainman, “Optofl uidic

1 × 4 switch,” Opt. Express, 16 (18), 13499–13508, 2008.) (f) Concept of operation of

1 × N optical switch—the fl uid on top of the grating is replaced to redirect the beam into

a certain order; the beam is incident from the bottom of the chamber shown on the

fi gure. (A. Groisman, S. Zamek, K. Campbell, L. Pang, U. Levy, and Y. Fainman,

“Optofl uidic 1 × 4 switch,” Opt. Express, 16 (18), 13499–13508, 2008.)