Page 45 - Optofluidics Fundamentals, Devices, and Applications

P. 45

26 Cha pte r T w o

I in I or

Liquid

W W W

Gas in m or

Liquid 500 μm

(a) (b)

Oil

h

w

Water (c)

L

W in

(d)

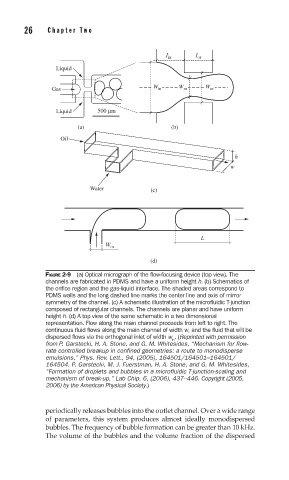

FIGURE 2-9 (a) Optical micrograph of the fl ow-focusing device (top view). The

channels are fabricated in PDMS and have a uniform height h. (b) Schematics of

the orifi ce region and the gas-liquid interface. The shaded areas correspond to

PDMS walls and the long dashed line marks the center line and axis of mirror

symmetry of the channel. (c) A schematic illustration of the microfl uidic T-junction

composed of rectangular channels. The channels are planar and have uniform

height h. (d) A top view of the same schematic in a two dimensional

representation. Flow along the main channel proceeds from left to right. The

continuous fl uid fl ows along the main channel of width w, and the fl uid that will be

dispersed fl ows via the orthogonal inlet of width w . (Reprinted with permission

in

from P. Garstecki, H. A. Stone, and G. M. Whitesides, “Mechanism for flow-

rate controlled breakup in confined geometries: a route to monodisperse

emulsions,” Phys. Rev. Lett., 94, (2005), 164501/164501–164501/

164504. P. Garstecki, M. J. Fuerstman, H. A. Stone, and G. M. Whitesides,

“Formation of droplets and bubbles in a microfluidic T-junction-scaling and

mechanism of break-up,” Lab Chip, 6, (2006), 437–446. Copyright (2005,

2006) by the American Physical Society.)

periodically releases bubbles into the outlet channel. Over a wide range

of parameters, this system produces almost ideally monodispersed

bubbles. The frequency of bubble formation can be greater than 10 kHz.

The volume of the bubbles and the volume fraction of the dispersed