Page 404 - Organic Electronics in Sensors and Biotechnology

P. 404

Electrophoretically Deposited Polymers for Organic Electronics 381

the findings, an optimum condition for a dispersed stable suspension

has been identified and applied to the EPD of PEEK particulates.

89

Wang and Kuwabara have demonstrated crack-free, relatively dense,

and smooth BaTiO film fabrication on the PANI layers-modified

3

Si substrate. This method provides a potential route for fabricating

ceramic films on the nonconductive Si or glass substrates using the

EPD technique.

90

Bohmer has studied the EPD of micron-sized polystyrene latex

particles on an ITO electrode using in situ optical microscopy. Bohmer

observed strong two-dimensional clustering of the particles on the

electrode surface upon application of a potential. Clustering decreases

somewhat with increasing salt concentration and breaks down upon

reversal of the direction of the field. A different interpretation has been

given to explain the clustering of polystyrene (PS) particles on the ITO

electrode surface. Tada and Onoda 11,12 have demonstrated the nano-

structured film fabrication of various conjugated polymers such as

poly(3-alkylthiophene), polyfluorene derivative, and MEH-PPV {poly[2-

(methoxy)-5-(2’-ethyl-hexyloxy)-1,4-phenylene vinylene]} etc. using

electrophoretic technique. They have utilized this technique to prepare

donor-acceptor nanocomposites consisting of conjugated conducting

polymers as donor and C molecules as acceptor. They have studied

10

60

these electrophoretically deposited nanostructured polymer films for

fabrication of organic light-emitting diodes, display devices, artificial

fingerprint devices, and photovoltaic applications. Dhand et al. 91

have recently reported the preparation of PANI/MWCNT composite

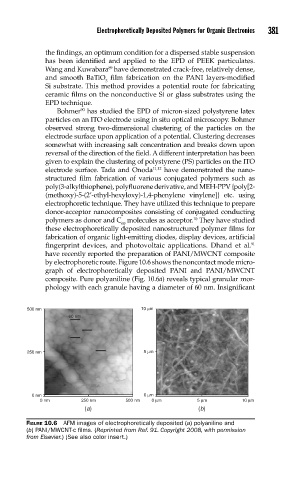

by electrophoretic route. Figure 10.6 shows the noncontact mode micro-

graph of electrophoretically deposited PANI and PANI/MWCNT

composite. Pure polyaniline (Fig. 10.6a) reveals typical granular mor-

phology with each granule having a diameter of 60 nm. Insignificant

500 nm 10 μm

60 nm

250 nm 5 μm

0 nm 0 μm

0 nm 250 nm 500 nm 0 μm 5 μm 10 μm

(a) (b)

FIGURE 10.6 AFM images of electrophoretically deposited (a) polyaniline and

(b) PANI/MWCNT-c fi lms. (Reprinted from Ref. 91. Copyright 2008, with permission

from Elsevier.) (See also color insert.)