Page 119 - Orlicky's Material Requirements Planning

P. 119

98 PART 2 Concepts

■ Under MRP, inventory control is action-oriented rather than clerical bookkeep-

ing–oriented.

■ Order quantities are related to requirements.

■ The timing of requirements, coverage, and order actions is emphasized.

Because of its focus on timing, an MRP system (and only an MRP system) can gen-

erate outputs that serve as valid inputs to other systems in the area of manufacturing

logistics, such as purchasing systems, shop scheduling systems, dispatching systems,

shop floor control systems, supply-chain planning systems, and capacity-requirements

planning systems. A sound MRP system constitutes a solid basis, a gateway, for other

computer applications in production and inven tory control.

The position of an inventory planning system, relative to other manufac turing logis-

tics functions or systems, is shown in Figure 6-1. The relation ships depicted in this chart

exist in any manufacturing company or plant. A manufacturing operation, in essence,

consists of the procurement of materials and the conversion of those materials into a ship-

pable product. The principal outputs of the inventory system, whatever this system may

be, are purchase requisitions and shop orders, each one of these calling for a specific

quantity of some inventory item. Any procurement or manufactur ing activity takes place

only after the inventory system has generated a call for the item. The inventory system

triggers all such activities. In terms of information flow, it is the upstream system.

Any and all systems along the two streams (procurement and manufactur ing) of

inventory system output are designed merely to execute the plan that is represented by

this output. These downstream systems cannot compensate for or improve the possibly

low quality (i.e., validity, accuracy, com pleteness, or timeliness) of the information they

receive as input. Regardless of how well implemented the downstream systems them-

selves may be, their real effectiveness still depends on the quality of the inputs they

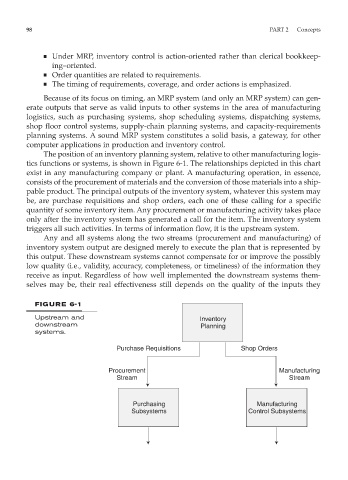

FIGURE 6-1

Upstream and Inventory

downstream Planning

systems.

Purchase Requisitions Shop Orders

Procurement Manufacturing

Stream Stream

Purchasing Manufacturing

Subsystems Control Subsystems