Page 121 - Orlicky's Material Requirements Planning

P. 121

100 PART 2 Concepts

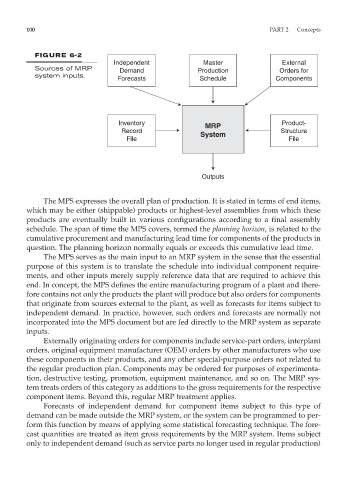

FIGURE 6-2

Independent Master External

Sources of MRP Demand Production Orders for

system inputs.

Forecasts Schedule Components

Inventory Product-

MRP

Record System Structure

File File

Outputs

The MPS expresses the overall plan of production. It is stated in terms of end items,

which may be either (shippable) products or highest-level assemblies from which these

products are eventually built in various configurations according to a final assembly

schedule. The span of time the MPS covers, termed the planning hori zon, is related to the

cumulative procurement and manufacturing lead time for components of the products in

question. The planning horizon normally equals or exceeds this cumulative lead time.

The MPS serves as the main input to an MRP sys tem in the sense that the essential

purpose of this system is to translate the schedule into individual component require-

ments, and other inputs merely supply reference data that are required to achieve this

end. In concept, the MPS defines the entire manufacturing program of a plant and there-

fore contains not only the products the plant will pro duce but also orders for components

that originate from sources external to the plant, as well as forecasts for items subject to

independent demand. In practice, however, such orders and forecasts are normally not

incor porated into the MPS document but are fed directly to the MRP system as separate

inputs.

Externally originating orders for components include service-part orders, interplant

orders, original equipment manufacturer (OEM) orders by other manufacturers who use

these components in their products, and any other special-purpose orders not related to

the regular production plan. Com ponents may be ordered for purposes of experimenta-

tion, destructive test ing, promotion, equipment maintenance, and so on. The MRP sys-

tem treats orders of this category as additions to the gross requirements for the respective

component items. Beyond this, regular MRP treatment applies.

Forecasts of independent demand for component items subject to this type of

demand can be made outside the MRP system, or the system can be programmed to per-

form this function by means of applying some statistical forecasting technique. The fore-

cast quantities are treated as item gross requirements by the MRP system. Items subject

only to independent demand (such as service parts no longer used in regular production)