Page 130 - Orlicky's Material Requirements Planning

P. 130

CHAPTER 6 The Material Requirements Planning System 109

the preceding example, it is assumed that lot sizing does not affect the lead time, that is,

that item lead time does not vary with the quantity being ordered.

Time phasing solves the problem of the effect of item lead time on the tim ing of

requirements. Lead-time values (or procedures for determining these values based on

order quantity) must be supplied to the MRP system, which stores them for use in estab-

lishing a proper alignment of requirements and planned-order data in the course of the

requirements explosion. Subtracting the lead time from the date of the net requirement,

that is, positioning the planned-order release forward of the timing of the net require-

ment it covers, is called offsetting for lead time.

Recurrence of Requirements Within the Planning Horizon

The planning horizon of the MPS usually covers a time span large enough to contain mul-

tiple (i.e., recurring) requirements for a given end item. This represents another complica-

tion in the computa tion of component requirements. The truck X example assumes that the

inventory quantities of all the component items involved are available for netting against

the gross requirements generated by the lot of 100 trucks. But there may be another lot (or

several) of the same end product (or of a different end product using the same transmis-

sion) that precedes the one for 100 in the MPS. If this is the case, its net require ments must

be accounted for before the net requirements for the lot of 100 can be determined.

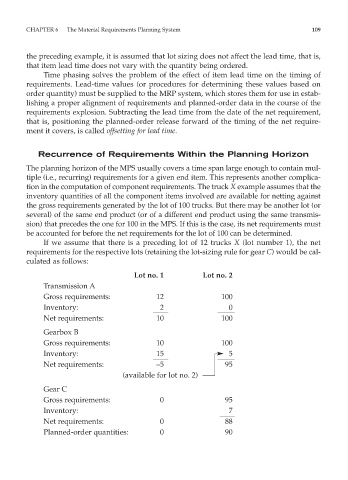

If we assume that there is a preceding lot of 12 trucks X (lot number 1), the net

requirements for the respective lots (retaining the lot-sizing rule for gear C) would be cal-

culated as follows:

Lot no. 1 Lot no. 2

Transmission A

Gross requirements: 12 100

Inventory: 2 0

Net requirements: 10 100

Gearbox B

Gross requirements: 10 100

Inventory: 15 5

Net requirements: –5 95

(available for lot no. 2)

Gear C

Gross requirements: 0 95

Inventory: 7

Net requirements: 0 88

Planned-order quantities: 0 90