Page 131 - Orlicky's Material Requirements Planning

P. 131

110 PART 2 Concepts

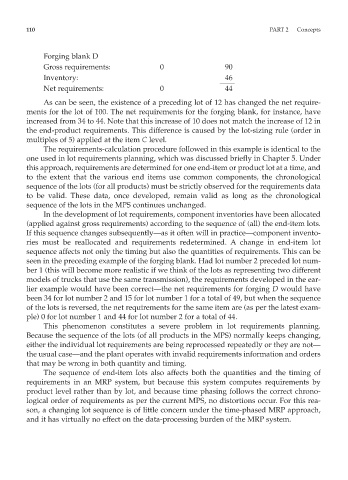

Forging blank D

Gross requirements: 0 90

Inventory: 46

Net requirements: 0 44

As can be seen, the existence of a preceding lot of 12 has changed the net require-

ments for the lot of 100. The net requirements for the forging blank, for instance, have

increased from 34 to 44. Note that this increase of 10 does not match the increase of 12 in

the end-product require ments. This difference is caused by the lot-sizing rule (order in

multiples of 5) applied at the item C level.

The requirements-calculation procedure followed in this example is identical to the

one used in lot requirements planning, which was discussed briefly in Chapter 5. Under

this approach, requirements are determined for one end-item or product lot at a time, and

to the extent that the various end items use common components, the chronological

sequence of the lots (for all products) must be strictly observed for the requirements data

to be valid. These data, once developed, remain valid as long as the chronological

sequence of the lots in the MPS continues unchanged.

In the development of lot requirements, component inventories have been allocated

(applied against gross requirements) according to the se quence of (all) the end-item lots.

If this sequence changes subsequently—as it often will in practice—component invento-

ries must be reallocated and requirements redetermined. A change in end-item lot

sequence affects not only the timing but also the quantities of requirements. This can be

seen in the preceding example of the forging blank. Had lot number 2 preceded lot num-

ber 1 (this will become more realistic if we think of the lots as representing two different

models of trucks that use the same transmission), the require ments developed in the ear-

lier example would have been correct—the net requirements for forging D would have

been 34 for lot number 2 and 15 for lot number 1 for a total of 49, but when the sequence

of the lots is reversed, the net requirements for the same item are (as per the latest exam-

ple) 0 for lot number 1 and 44 for lot number 2 for a total of 44.

This phenomenon constitutes a severe problem in lot requirements plan ning.

Because the sequence of the lots (of all products in the MPS) normally keeps changing,

either the individual lot require ments are being reprocessed repeatedly or they are not—

the usual case—and the plant operates with invalid requirements information and orders

that may be wrong in both quantity and timing.

The sequence of end-item lots also affects both the quantities and the timing of

requirements in an MRP system, but because this system computes requirements by

product level rather than by lot, and because time phasing follows the correct chrono-

logical order of requirements as per the current MPS, no distortions occur. For this rea-

son, a chang ing lot sequence is of little concern under the time-phased MRP approach,

and it has virtually no effect on the data-process ing burden of the MRP system.