Page 215 - Orlicky's Material Requirements Planning

P. 215

194 PART 3 Managing with the MRP System

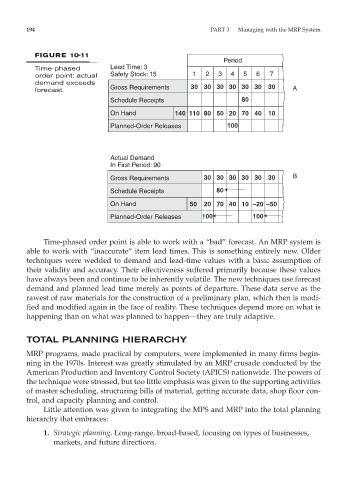

FIGURE 10-11

Period

Time-phased Lead Time: 3

order point: actual Safety Stock: 15 1 2 3 4 5 6 7

demand exceeds

forecast. Gross Requirements 30 30 30 30 30 30 30 A

Schedule Receipts 80

On Hand 140 110 80 50 20 70 40 10

Planned-Order Releases 100

Actual Demand

In First Period: 90

Gross Requirements 30 30 30 30 30 30 B

Schedule Receipts 80

On Hand 50 20 70 40 10 –20 –50

Planned-Order Releases 100 100

Time-phased order point is able to work with a “bad” forecast. An MRP system is

able to work with “inaccurate” item lead times. This is something entirely new. Older

techniques were wedded to demand and lead-time values with a basic assumption of

their validity and accuracy. Their effectiveness suffered primarily because these values

have always been and continue to be inherently volatile. The new techniques use forecast

demand and planned lead time merely as points of departure. These data serve as the

rawest of raw materials for the construction of a preliminary plan, which then is modi-

fied and modified again in the face of reality. These techniques depend more on what is

happening than on what was planned to happen—they are truly adaptive.

TOTAL PLANNING HIERARCHY

MRP programs, made practical by computers, were implemented in many firms begin-

ning in the 1970s. Interest was greatly stimulated by an MRP crusade conducted by the

American Production and Inventory Control Society (APICS) nationwide. The powers of

the technique were stressed, but too little emphasis was given to the support ing activities

of master scheduling, structuring bills of material, getting accurate data, shop floor con-

trol, and capacity planning and control.

Little attention was given to integrating the MPS and MRP into the total planning

hierarchy that embraces:

1. Strategic planning. Long-range, broad-based, focusing on types of businesses,

markets, and future directions.