Page 211 - Orlicky's Material Requirements Planning

P. 211

190 PART 3 Managing with the MRP System

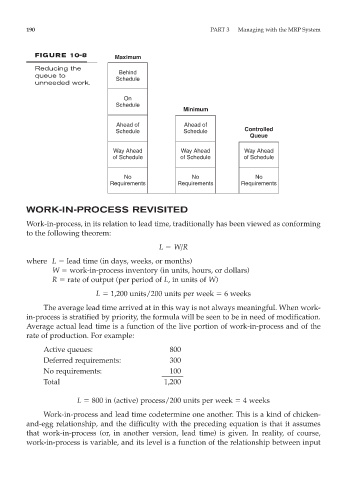

FIGURE 10-8 Maximum

Reducing the

Behind

queue to

Schedule

unneeded work.

On

Schedule

Minimum

Ahead of Ahead of

Schedule Schedule Controlled

Queue

Way Ahead Way Ahead Way Ahead

of Schedule of Schedule of Schedule

No No No

Requirements Requirements Requirements

WORK-IN-PROCESS REVISITED

Work-in-process, in its relation to lead time, traditionally has been viewed as conforming

to the following theorem:

L W/R

where L lead time (in days, weeks, or months)

W work-in-process inventory (in units, hours, or dollars)

R rate of output (per period of L, in units of W)

L 1,200 units/200 units per week 6 weeks

The average lead time arrived at in this way is not always meaningful. When work-

in-process is stratified by priority, the formula will be seen to be in need of modification.

Average actual lead time is a function of the live portion of work-in-process and of the

rate of production. For example:

Active queues: 800

Deferred requirements: 300

No requirements: 100

Total 1,200

L 800 in (active) process/200 units per week 4 weeks

Work-in-process and lead time codetermine one another. This is a kind of chicken-

and-egg relationship, and the difficulty with the preceding equation is that it assumes

that work-in-process (or, in another version, lead time) is given. In reality, of course,

work-in-process is variable, and its level is a function of the relationship between input