Page 213 - Orlicky's Material Requirements Planning

P. 213

192 PART 3 Managing with the MRP System

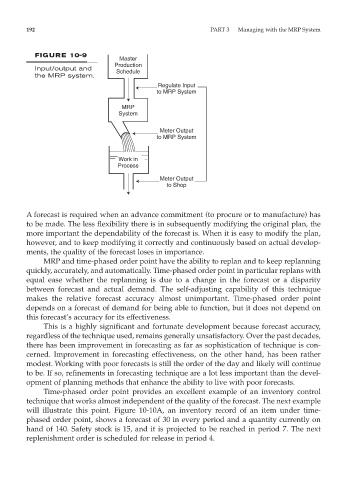

FIGURE 10-9

Master

Production

Input/output and Schedule

the MRP system.

Regulate Input

to MRP System

MRP

System

Meter Output

to MRP System

Work in

Process

Meter Output

to Shop

A forecast is required when an advance commitment (to procure or to manufacture) has

to be made. The less flexibility there is in subsequently modifying the original plan, the

more important the dependability of the forecast is. When it is easy to modify the plan,

however, and to keep modifying it correctly and continuously based on actual develop-

ments, the quality of the forecast loses in importance.

MRP and time-phased order point have the ability to replan and to keep replanning

quickly, accurately, and automatically. Time-phased order point in particular replans with

equal ease whether the replanning is due to a change in the forecast or a disparity

between forecast and actual demand. The self-adjusting capability of this technique

makes the relative forecast accuracy almost unimportant. Time-phased order point

depends on a forecast of demand for being able to function, but it does not depend on

this forecast’s accuracy for its effectiveness.

This is a highly significant and fortunate development because forecast accuracy,

regardless of the technique used, remains generally unsatisfactory. Over the past decades,

there has been improvement in forecasting as far as sophistication of technique is con-

cerned. Improvement in forecasting effectiveness, on the other hand, has been rather

modest. Working with poor forecasts is still the order of the day and likely will continue

to be. If so, refinements in forecasting technique are a lot less important than the devel-

opment of planning methods that enhance the ability to live with poor forecasts.

Time-phased order point provides an excellent example of an inventory control

technique that works almost independent of the quality of the forecast. The next example

will illustrate this point. Figure 10-10A, an inventory record of an item under time-

phased order point, shows a forecast of 30 in every period and a quantity currently on

hand of 140. Safety stock is 15, and it is projected to be reached in period 7. The next

replenishment order is scheduled for release in period 4.