Page 253 - Orlicky's Material Requirements Planning

P. 253

232 PART 3 Managing with the MRP System

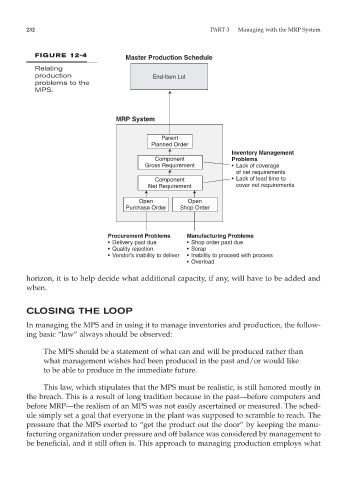

FIGURE 12-4

Master Production Schedule

Relating

production End-Item Lot

problems to the

MPS.

MRP System

Parent

Planned Order

Inventory Management

Component Problems

Gross Requirement • Lack of coverage

of net requirements

Component • Lack of lead time to

Net Requirement cover net requirements

Open Open

Purchase Order Shop Order

Procurement Problems Manufacturing Problems

• Delivery past due • Shop order past due

• Quality rejection • Scrap

• Vendor’s inability to deliver • Inability to proceed with process

• Overload

horizon, it is to help decide what additional capacity, if any, will have to be added and

when.

CLOSING THE LOOP

In managing the MPS and in using it to manage inventories and production, the follow-

ing basic “law” always should be observed:

The MPS should be a statement of what can and will be produced rather than

what management wishes had been produced in the past and/or would like

to be able to produce in the immediate future.

This law, which stipulates that the MPS must be realistic, is still honored mostly in

the breach. This is a result of long tradition because in the past—before computers and

before MRP—the realism of an MPS was not easily ascertained or measured. The sched-

ule simply set a goal that everyone in the plant was supposed to scramble to reach. The

pressure that the MPS exerted to “get the product out the door” by keeping the manu-

facturing organization under pressure and off balance was considered by management to

be beneficial, and it still often is. This approach to managing production employs what