Page 279 - Orlicky's Material Requirements Planning

P. 279

258 PART 3 Managing with the MRP System

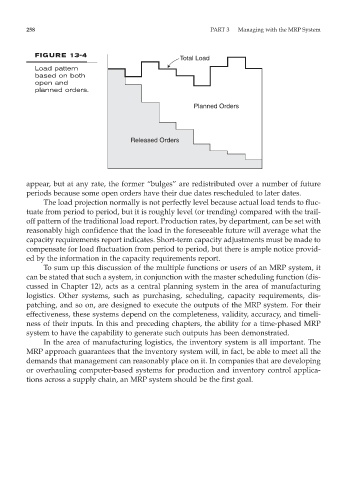

FIGURE 13-4

Total Load

Load pattern

based on both

open and

planned orders.

Planned Orders

Released Orders

appear, but at any rate, the former “bulges” are redistributed over a number of future

periods because some open orders have their due dates rescheduled to later dates.

The load projection normally is not perfectly level because actual load tends to fluc-

tuate from period to period, but it is roughly level (or trending) compared with the trail-

off pattern of the traditional load report. Production rates, by department, can be set with

reasonably high confidence that the load in the foreseeable future will average what the

capacity requirements report indicates. Short-term capacity adjustments must be made to

compensate for load fluctuation from period to period, but there is ample notice provid-

ed by the information in the capacity requirements report.

To sum up this discussion of the multiple functions or users of an MRP system, it

can be stated that such a system, in conjunction with the master scheduling function (dis-

cussed in Chapter 12), acts as a central planning system in the area of manufacturing

logistics. Other systems, such as purchasing, scheduling, capacity requirements, dis-

patching, and so on, are designed to execute the outputs of the MRP system. For their

effectiveness, these systems depend on the completeness, validity, accuracy, and timeli-

ness of their inputs. In this and preceding chapters, the ability for a time-phased MRP

system to have the capability to generate such outputs has been demonstrated.

In the area of manufacturing logistics, the inventory system is all important. The

MRP approach guarantees that the inventory system will, in fact, be able to meet all the

demands that management can reasonably place on it. In companies that are developing

or overhauling computer-based systems for production and inventory control applica-

tions across a supply chain, an MRP system should be the first goal.