Page 33 - Orlicky's Material Requirements Planning

P. 33

14 PART 1 Perspective

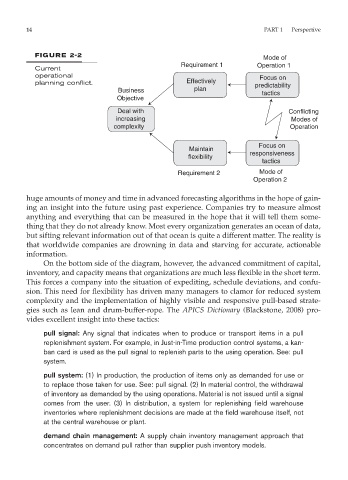

FIGURE 2-2

Mode of

Requirement 1 Operation 1

Current

operational Focus on

planning conflict. Effectively predictability

Business plan

tactics

Objective

Deal with Conflicting

increasing Modes of

complexity Operation

Focus on

Maintain

flexibility responsiveness

tactics

Requirement 2 Mode of

Operation 2

huge amounts of money and time in advanced forecasting algorithms in the hope of gain-

ing an insight into the future using past experience. Companies try to measure almost

anything and everything that can be measured in the hope that it will tell them some-

thing that they do not already know. Most every organization generates an ocean of data,

but sifting relevant information out of that ocean is quite a different matter. The reality is

that worldwide companies are drowning in data and starving for accurate, actionable

information.

On the bottom side of the diagram, however, the advanced commitment of capital,

inventory, and capacity means that organizations are much less flexible in the short term.

This forces a company into the situation of expediting, schedule deviations, and confu-

sion. This need for flexibility has driven many managers to clamor for reduced system

complexity and the implementation of highly visible and responsive pull-based strate-

gies such as lean and drum-buffer-rope. The APICS Dictionary (Blackstone, 2008) pro-

vides excellent insight into these tactics:

pull signal: Any signal that indicates when to produce or transport items in a pull

replenishment system. For example, in Just-in-Time production control systems, a kan-

ban card is used as the pull signal to replenish parts to the using operation. See: pull

system.

pull system: (1) In production, the production of items only as demanded for use or

to replace those taken for use. See: pull signal. (2) In material control, the withdrawal

of inventory as demanded by the using operations. Material is not issued until a signal

comes from the user. (3) In distribution, a system for replenishing field warehouse

inventories where replenishment decisions are made at the field warehouse itself, not

at the central warehouse or plant.

demand chain management: A supply chain inventory management approach that

concentrates on demand pull rather than supplier push inventory models.