Page 35 - Orlicky's Material Requirements Planning

P. 35

16 PART 1 Perspective

chain(s). W. Edwards Deming and Walter Shewhart clearly understood this concept with

respect to the quality a company can produce. Deming and Shewhart taught process con-

trol and continuous improvement for years in the United States. Because American

industry did not realize the impact that these critical tools could have on the bottom line,

Deming eventually went to Japan. The rest, as they say, is history. Several years before his

death, Deming came back to this country, and finally, the market was ready to listen.

Reducing variation is core to the six sigma process-improvement approach.

Understanding and dealing with variability are even more important today because vari-

ability and volatility are on a dramatic rise.

Recently, companies have been caught between a rock and a hard place with regard

to solving the conflict inherent in the preceding three questions. In the last decade, many

companies, in the attempt to embrace lean concepts, including the dramatic reduction of

inventory everywhere, leaned out so much that they actually exposed themselves to

increased variability and volatility. By treating inventory as a waste, they actually expe-

rienced the opposite effect and made their supply chains too brittle and less agile.

Variability can be systematically minimized and managed but not eliminated. The

biggest challenge in attacking all the causes for variability and minimizing their individ-

ual impact on the system is the investment of time, effort, and money to get there and the

return on that investment. The six sigma toolset provides an excellent approach to reduce

variability, but even the best master black belt cannot totally eliminate variability. This is

not to say that companies should not seek to use these tools that identify and dampen the

variability noise. These tools, however, are complementary rather than primary to the

materials planning function.

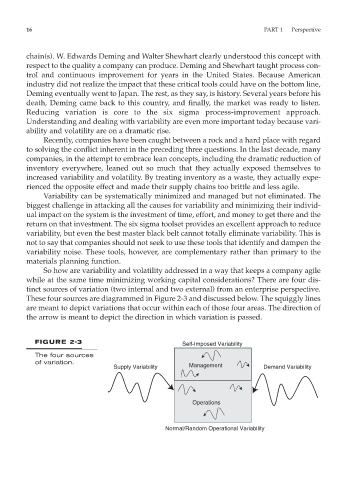

So how are variability and volatility addressed in a way that keeps a company agile

while at the same time minimizing working capital considerations? There are four dis-

tinct sources of variation (two internal and two external) from an enterprise perspective.

These four sources are diagrammed in Figure 2-3 and discussed below. The squiggly lines

are meant to depict variations that occur within each of those four areas. The direction of

the arrow is meant to depict the direction in which variation is passed.

FIGURE 2-3 Self-Imposed Variability

The four sources

of variation.

Supply Variability Management Demand Variability

Operations

Normal/Random Operational Variability