Page 37 - Orlicky's Material Requirements Planning

P. 37

18 PART 1 Perspective

age. We cannot remove the human element, but the damaging aspect of the human ele-

ment (the assignable cause) can be addressed.

Net Effect of Variation on Operations and Supply Chains

MRP Nervousness The APICS Dictionary (New York: Blackstone, 2007, p. 86)

defines nervousness as

The characteristic in an MRP system when minor changes in higher level (e.g., level 0

or 1) records or the master production schedule cause significant timing or quantity

changes in lower level (e.g., 5 or 6) schedules or orders.

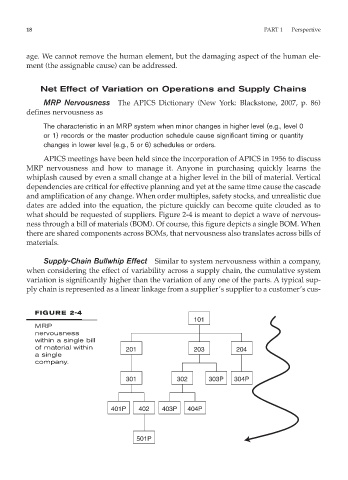

APICS meetings have been held since the incorporation of APICS in 1956 to discuss

MRP nervousness and how to manage it. Anyone in purchasing quickly learns the

whiplash caused by even a small change at a higher level in the bill of material. Vertical

dependencies are critical for effective planning and yet at the same time cause the cascade

and amplification of any change. When order multiples, safety stocks, and unrealistic due

dates are added into the equation, the picture quickly can become quite clouded as to

what should be requested of suppliers. Figure 2-4 is meant to depict a wave of nervous-

ness through a bill of materials (BOM). Of course, this figure depicts a single BOM. When

there are shared components across BOMs, that nervousness also translates across bills of

materials.

Supply-Chain Bullwhip Effect Similar to system nervousness within a company,

when considering the effect of variability across a supply chain, the cumulative system

variation is significantly higher than the variation of any one of the parts. A typical sup-

ply chain is represented as a linear linkage from a supplier’s supplier to a customer’s cus-

FIGURE 2-4

101

MRP

nervousness

within a single bill

of material within 201 203 204

a single

company.

301 302 303P 304P

401P 402 403P 404P

501P