Page 409 - Orlicky's Material Requirements Planning

P. 409

388 PART 4 Looking Backward and Forward

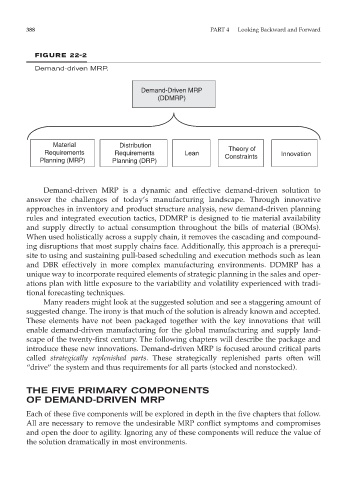

FIGURE 22-2

Demand-driven MRP.

Demand-Driven MRP

(DDMRP)

Material Distribution

Requirements Requirements Lean Theory of Innovation

Planning (MRP) Planning (DRP) Constraints

Demand-driven MRP is a dynamic and effective demand-driven solution to

answer the challenges of today’s manufacturing landscape. Through innovative

approaches in inventory and product structure analysis, new demand-driven planning

rules and integrated execution tactics, DDMRP is designed to tie material availability

and supply directly to actual consumption throughout the bills of material (BOMs).

When used holistically across a supply chain, it removes the cascading and compound-

ing disruptions that most supply chains face. Additionally, this approach is a prerequi-

site to using and sustaining pull-based scheduling and execution methods such as lean

and DBR effectively in more complex manufacturing environments. DDMRP has a

unique way to incorporate required elements of strategic planning in the sales and oper-

ations plan with little exposure to the variability and volatility experienced with tradi-

tional forecasting techniques.

Many readers might look at the suggested solution and see a staggering amount of

suggested change. The irony is that much of the solution is already known and accepted.

These elements have not been packaged together with the key innovations that will

enable demand-driven manufacturing for the global manufacturing and supply land-

scape of the twenty-first century. The following chapters will describe the package and

introduce these new innovations. Demand-driven MRP is focused around critical parts

called strategically replenished parts. These strategically replenished parts often will

“drive” the system and thus requirements for all parts (stocked and nonstocked).

THE FIVE PRIMARY COMPONENTS

OF DEMAND-DRIVEN MRP

Each of these five components will be explored in depth in the five chapters that follow.

All are necessary to remove the undesirable MRP conflict symptoms and compromises

and open the door to agility. Ignoring any of these components will reduce the value of

the solution dramatically in most environments.