Page 414 - Orlicky's Material Requirements Planning

P. 414

CHAPTER 23 Strategic Inventory Positioning 393

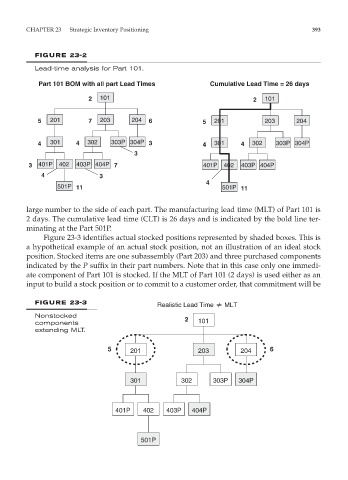

FIGURE 23-2

Lead-time analysis for Part 101.

Part 101 BOM with all part Lead Times Cumulative Lead Time = 26 days

2 101 2 101

5 201 7 203 204 6 5 201 203 204

4 301 4 302 303P 304P 3 4 301 4 302 303P 304P

3

3 401P 402 403P 404P 7 401P 402 403P 404P

4 3

4

501P 11 501P 11

large number to the side of each part. The manufacturing lead time (MLT) of Part 101 is

2 days. The cumulative lead time (CLT) is 26 days and is indicated by the bold line ter-

minating at the Part 501P.

Figure 23-3 identifies actual stocked positions represented by shaded boxes. This is

a hypothetical example of an actual stock position, not an illustration of an ideal stock

position. Stocked items are one subassembly (Part 203) and three purchased components

indicated by the P suffix in their part numbers. Note that in this case only one immedi-

ate component of Part 101 is stocked. If the MLT of Part 101 (2 days) is used either as an

input to build a stock position or to commit to a customer order, that commitment will be

FIGURE 23-3 Realistic Lead Time MLT

Nonstocked 2

components 101

extending MLT.

5 201 203 204 6

301 302 303P 304P

401P 402 403P 404P

501P