Page 419 - Orlicky's Material Requirements Planning

P. 419

398 PART 4 Looking Backward and Forward

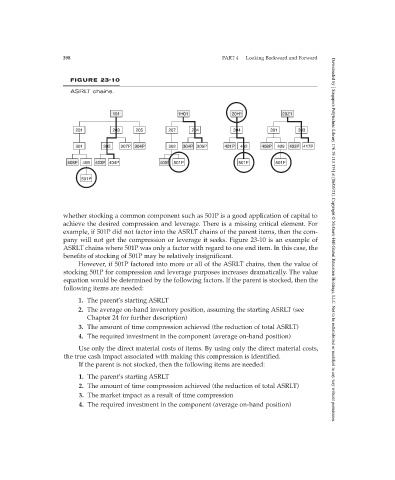

FIGURE 23-10

ASRLT chains.

101 1H01 20H1 20Z1

201 203 205 207 204 304 301 303

301 305 307P 304P 302 304P 309P 401P 402 408P 409 403P 417P

408P 409 403P 404P 403P 501P 501P 501P

501P

whether stocking a common component such as 501P is a good application of capital to

achieve the desired compression and leverage. There is a missing critical element. For

example, if 501P did not factor into the ASRLT chains of the parent items, then the com-

pany will not get the compression or leverage it seeks. Figure 23-10 is an example of Downloaded by [ Singapore Polytechnic Library 176.79.113.174] at [06/05/21]. Copyright © McGraw-Hill Global Education Holdings, LLC. Not to be redistributed or modified in any way without permission.

ASRLT chains where 501P was only a factor with regard to one end item. In this case, the

benefits of stocking of 501P may be relatively insignificant.

However, if 501P factored into more or all of the ASRLT chains, then the value of

stocking 501P for compression and leverage purposes increases dramatically. The value

equation would be determined by the following factors. If the parent is stocked, then the

following items are needed:

1. The parent’s starting ASRLT

2. The average on-hand inventory position, assuming the starting ASRLT (see

Chapter 24 for further description)

3. The amount of time compression achieved (the reduction of total ASRLT)

4. The required investment in the component (average on-hand position)

Use only the direct material costs of items. By using only the direct material costs,

the true cash impact associated with making this compression is identified.

If the parent is not stocked, then the following items are needed:

1. The parent’s starting ASRLT

2. The amount of time compression achieved (the reduction of total ASRLT)

3. The market impact as a result of time compression

4. The required investment in the component (average on-hand position)