Page 418 - Orlicky's Material Requirements Planning

P. 418

CHAPTER 23 Strategic Inventory Positioning 397

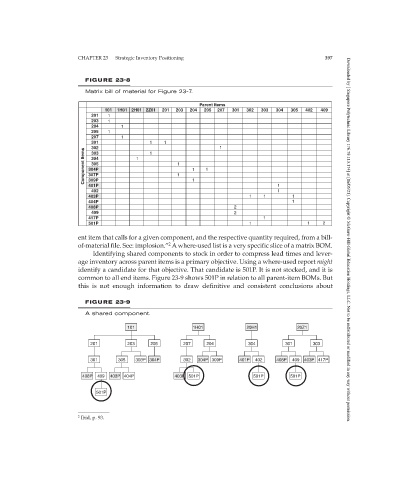

FIGURE 23-8

Matrix bill of material for Figure 23-7.

Parent Items

101 1H01 2H01 2Z01 201 203 204 205 207 301 302 303 304 305 402 409

201 1

203 1

204 1

205 1

207 1

301 1 1 1 1

302

Component Items 304P 1 1 1 1 1

303

304

305

307P

309P

401P 1 1

402 1

403P 1 1 1

404P 1

408P 2

409 2

417P 1

501P 1 1 2

ent item that calls for a given component, and the respective quantity required, from a bill- Downloaded by [ Singapore Polytechnic Library 176.79.113.174] at [06/05/21]. Copyright © McGraw-Hill Global Education Holdings, LLC. Not to be redistributed or modified in any way without permission.

2

of-material file. See: implosion.” A where-used list is a very specific slice of a matrix BOM.

Identifying shared components to stock in order to compress lead times and lever-

age inventory across parent items is a primary objective. Using a where-used report might

identify a candidate for that objective. That candidate is 501P. It is not stocked, and it is

common to all end items. Figure 23-9 shows 501P in relation to all parent-item BOMs. But

this is not enough information to draw definitive and consistent conclusions about

FIGURE 23-9

A shared component.

101 1H01 20H1 20Z1

201 203 205 207 204 304 301 303

301 305 303P 304P 302 304P 309P 401P 402 408P 409 403P 417P

408P 409 403P 404P 403P 501P 501P 501P

501P

2 Ibid, p. 93.