Page 175 - Photodetection and Measurement - Maximizing Performance in Optical Systems

P. 175

Stability and Tempco Issues

168 Chapter Eight

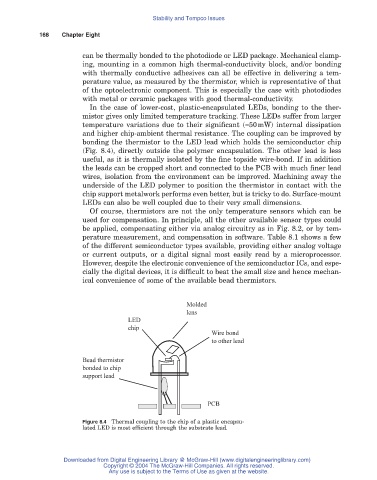

can be thermally bonded to the photodiode or LED package. Mechanical clamp-

ing, mounting in a common high thermal-conductivity block, and/or bonding

with thermally conductive adhesives can all be effective in delivering a tem-

perature value, as measured by the thermistor, which is representative of that

of the optoelectronic component. This is especially the case with photodiodes

with metal or ceramic packages with good thermal-conductivity.

In the case of lower-cost, plastic-encapsulated LEDs, bonding to the ther-

mistor gives only limited temperature tracking. These LEDs suffer from larger

temperature variations due to their significant (ª50mW) internal dissipation

and higher chip-ambient thermal resistance. The coupling can be improved by

bonding the thermistor to the LED lead which holds the semiconductor chip

(Fig. 8.4), directly outside the polymer encapsulation. The other lead is less

useful, as it is thermally isolated by the fine topside wire-bond. If in addition

the leads can be cropped short and connected to the PCB with much finer lead

wires, isolation from the environment can be improved. Machining away the

underside of the LED polymer to position the thermistor in contact with the

chip support metalwork performs even better, but is tricky to do. Surface-mount

LEDs can also be well coupled due to their very small dimensions.

Of course, thermistors are not the only temperature sensors which can be

used for compensation. In principle, all the other available sensor types could

be applied, compensating either via analog circuitry as in Fig. 8.2, or by tem-

perature measurement, and compensation in software. Table 8.1 shows a few

of the different semiconductor types available, providing either analog voltage

or current outputs, or a digital signal most easily read by a microprocessor.

However, despite the electronic convenience of the semiconductor ICs, and espe-

cially the digital devices, it is difficult to beat the small size and hence mechan-

ical convenience of some of the available bead thermistors.

Molded

lens

LED

chip

Wire bond

to other lead

Bead thermistor

bonded to chip

support lead

PCB

Figure 8.4 Thermal coupling to the chip of a plastic encapsu-

lated LED is most efficient through the substrate lead.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.