Page 150 - Pipeline Pigging Technology

P. 150

The Zeepipe challenge

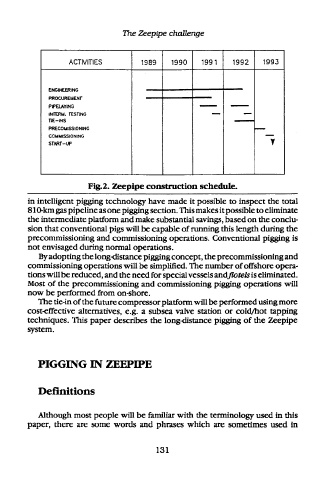

Fig.2. Zeepipe construction schedule.

in intelligent pigging technology have made it possible to inspect the total

810-km gas pipeline as one pigging section. This makes it possible to eliminate

the intermediate platform and make substantial savings, based on the conclu-

sion that conventional pigs will be capable of running this length during the

precommissioning and commissioning operations. Conventional pigging is

not envisaged during normal operations.

By adopting the long-distance pigging concept, the precommissioning and

commissioning operations will be simplified. The number of offshore opera-

tions will be reduced, and the need for special vessels andflotels is eliminated.

Most of the precommissioning and commissioning pigging operations will

now be performed from on-shore.

The tie-in of the future compressor platform will be performed using more

cost-effective alternatives, e.g. a subsea valve station or cold/hot tapping

techniques. This paper describes the long-distance pigging of the Zeepipe

system.

PIGGING IN ZEEPIPE

Definitions

Although most people will be familiar with the terminology used in this

paper, there are some words and phrases which are sometimes used in

131