Page 155 - Pipeline Pigging Technology

P. 155

Pipeline Pigging Technology

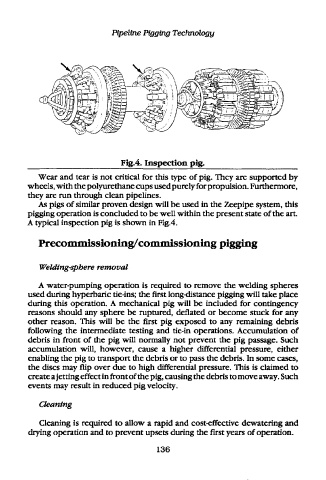

Fig.4. Inspection pig.

Wear and tear is not critical for this type of pig. They are supported by

wheels, with the polyurethane cups used purely for propulsion. Furthermore,

they are run through clean pipelines.

As pigs of similar proven design will be used in the Zeepipe system, this

pigging operation is concluded to be well within the present state of the art.

A typical inspection pig is shown in Fig.4.

Precommissioning/commissioning pigging

Welding-sphere removal

A water-pumping operation is required to remove the welding spheres

used during hyperbaric tie-ins; the first long-distance pigging will take place

during this operation. A mechanical pig will be included for contingency

reasons should any sphere be ruptured, deflated or become stuck for any

other reason. This will be the first pig exposed to any remaining debris

following the intermediate testing and tie-in operations. Accumulation of

debris in front of the pig will normally not prevent the pig passage. Such

accumulation will, however, cause a higher differential pressure, either

enabling the pig to transport the debris or to pass the debris. In some cases,

the discs may flip over due to high differential pressure. This is claimed to

create a jetting effect in front of the pig, causing the debris to move away. Such

events may result in reduced pig velocity.

Cleaning

Cleaning is required to allow a rapid and cost-effective dewatering and

drying operation and to prevent upsets during the first years of operation.

136