Page 158 - Pipeline Pigging Technology

P. 158

The Zeepipe challenge

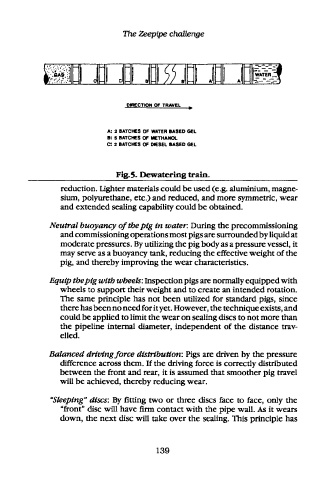

Fig. 5. Dewatering train.

reduction. Lighter materials could be used (e.g. aluminium, magne-

sium, polyurethane, etc.) and reduced, and more symmetric, wear

and extended sealing capability could be obtained.

Neutral buoyancy of the pig in water: During the precommissioning

and commissioning operations most pigs are surrounded by liquid at

moderate pressures. By utilizing the pig body as a pressure vessel, it

may serve as a buoyancy tank, reducing the effective weight of the

pig, and thereby improving the wear characteristics.

Equip the pig with wheels: Inspection pigs are normally equipped with

wheels to support their weight and to create an intended rotation.

The same principle has not been utilized for standard pigs, since

there has been no need for it yet. However, the technique exists, and

could be applied to limit the wear on sealing discs to not more than

the pipeline internal diameter, independent of the distance trav-

elled.

Balanced driving force distribution: Pigs are driven by the pressure

difference across them. If the driving force is correctly distributed

between the front and rear, it is assumed that smoother pig travel

will be achieved, thereby reducing wear.

"Sleeping" discs: By fitting two or three discs face to face, only the

"front" disc will have firm contact with the pipe wall. As it wears

down, the next disc will take over the sealing. This principle has

139