Page 154 - Pipeline Pigging Technology

P. 154

The Zeepipe challenge

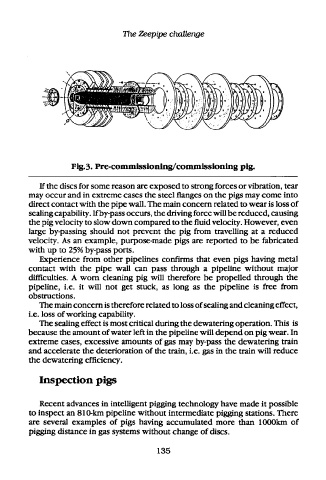

Fig.3. Pre-commissioning/comniissioning pig.

If the discs for some reason are exposed to strong forces or vibration, tear

may occur and in extreme cases the steel flanges on the pigs may come into

direct contact with the pipe wall. The main concern related to wear is loss of

sealing capability. If by-pass occurs, the driving force will be reduced, causing

the pig velocity to slow down compared to the fluid velocity. However, even

large by-passing should not prevent the pig from travelling at a reduced

velocity. As an example, purpose-made pigs are reported to be fabricated

with up to 25% by-pass ports.

Experience from other pipelines confirms that even pigs having metal

contact with the pipe wall can pass through a pipeline without major

difficulties. A worn cleaning pig will therefore be propelled through the

pipeline, i.e. it will not get stuck, as long as the pipeline is free from

obstructions.

The main concern is therefore related to loss of sealing and cleaning effect,

i.e. loss of working capability.

The sealing effect is most critical during the dewatering operation. This is

because the amount of water left in the pipeline will depend on pig wear. In

extreme cases, excessive amounts of gas may by-pass the dewatering train

and accelerate the deterioration of the train, i.e. gas in the train will reduce

the dewatering efficiency.

Inspection pigs

Recent advances in intelligent pigging technology have made it possible

to inspect an 810-km pipeline without intermediate pigging stations. There

are several examples of pigs having accumulated more than 1000km of

pigging distance in gas systems without change of discs.

135