Page 190 - Pipeline Pigging Technology

P. 190

Gellypig technology for pipeline conversion

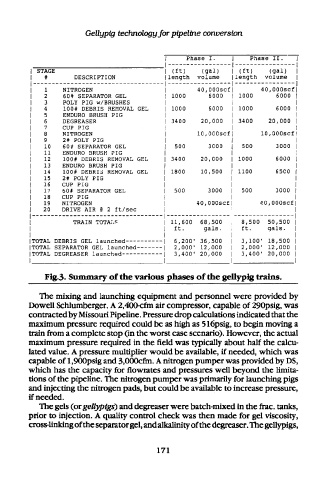

Fig.3. Summary of the various phases of the gellyplg trains.

The mixing and launching equipment and personnel were provided by

Dowell Schlumberger. A 2,400-cfm air compressor, capable of 290psig, was

contracted by Missouri Pipeline. Pressure drop calculations indicated that the

maximum pressure required could be as high as 5l6psig, to begin moving a

train from a complete stop (in the worst case scenario). However, the actual

maximum pressure required in the field was typically about half the calcu-

lated value. A pressure multiplier would be available, if needed, which was

capable of 1,900psig and 3,000cfm. A nitrogen pumper was provided by DS,

which has the capacity for flowrates and pressures well beyond the limita-

tions of the pipeline. The nitrogen pumper was primarily for launching pigs

and injecting the nitrogen pads, but could be available to increase pressure,

if needed.

The gels (or geltypigs) and degreaser were batch-mixed in the frac. tanks,

prior to injection. A quality control check was then made for gel viscosity,

cross-linking of the separator gel, and alkalinity of the degreaser. The gellypigs,

171