Page 249 - Pipeline Pigging Technology

P. 249

Pipeline Pigging Technology

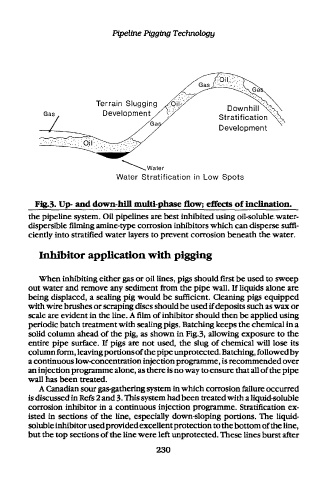

Fig.3. Up- and down-hill multi-phase flow; effects of inclination.

the pipeline system. Oil pipelines are best inhibited using oil-soluble water-

dispersible filming amine-type corrosion inhibitors which can disperse suffi-

ciently into stratified water layers to prevent corrosion beneath the water.

Inhibitor application with pigging

When inhibiting either gas or oil lines, pigs should first be used to sweep

out water and remove any sediment from the pipe wall. If liquids alone are

being displaced, a sealing pig would be sufficient. Cleaning pigs equipped

with wire brushes or scraping discs should be used if deposits such as wax or

scale are evident in the line. A film of inhibitor should then be applied using

periodic batch treatment with sealing pigs. Batching keeps the chemical in a

solid column ahead of the pig, as shown in Fig.3, allowing exposure to the

entire pipe surface. If pigs are not used, the slug of chemical will lose its

column form, leaving portions of the pipe unprotected. Batching, followed by

a continuous low-concentration injection programme, is recommended over

an injection programme alone, as there is no way to ensure that all of the pipe

wall has been treated.

A Canadian sour gas-gathering system in which corrosion failure occurred

is discussed in Refs 2 and 3. This system had been treated with a liquid-soluble

corrosion inhibitor in a continuous injection programme. Stratification ex-

isted in sections of the line, especially down-sloping portions. The liquid-

soluble inhibitor used provided excellent protection to the bottom of the line,

but the top sections of the line were left unprotected. These lines burst after

230