Page 253 - Pipeline Pigging Technology

P. 253

Pipeline Pigging Technology

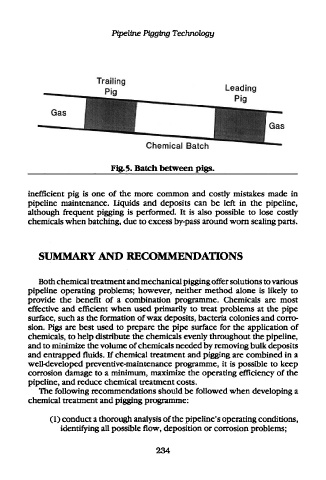

Fig. 5. Batch between pigs.

inefficient pig is one of the more common and costly mistakes made in

pipeline maintenance. Liquids and deposits can be left in the pipeline,

although frequent pigging is performed. It is also possible to lose costly

chemicals when batching, due to excess by-pass around worn sealing parts.

SUMMARY AND RECOMMENDATIONS

Both chemical treatment and mechanical pigging offer solutions to various

pipeline operating problems; however, neither method alone is likely to

provide the benefit of a combination programme. Chemicals are most

effective and efficient when used primarily to treat problems at the pipe

surface, such as the formation of wax deposits, bacteria colonies and corro-

sion. Pigs are best used to prepare the pipe surface for the application of

chemicals, to help distribute the chemicals evenly throughout the pipeline,

and to minimize the volume of chemicals needed by removing bulk deposits

and entrapped fluids. If chemical treatment and pigging are combined in a

well-developed preventive-maintenance programme, it is possible to keep

corrosion damage to a minimum, maximize the operating efficiency of the

pipeline, and reduce chemical treatment costs.

The following recommendations should be followed when developing a

chemical treatment and pigging programme:

(1) conduct a thorough analysis of the pipeline's operating conditions,

identifying all possible flow, deposition or corrosion problems;

234