Page 96 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 96

4/74 Corrosion Index

effectiveness in any operational measure purported to reduce The evaluator assesses the situation as follows:

internal corrosion potential.

A. Product corrosivity 5 pts

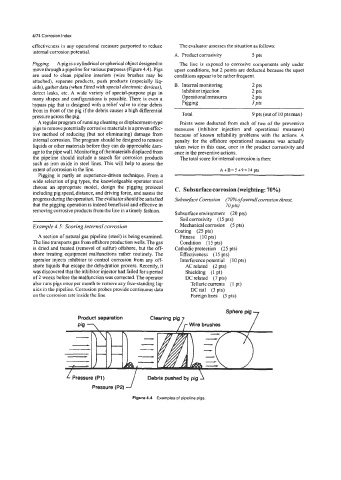

Pigging A pig is a cylindrical or spherical object designed to The line is exposed to corrosive components only under

move through a pipeline for various purposes (Figure 4.4). Pigs upset conditions, but 2 points are deducted because the upset

are used to clean pipeline interiors (wire brushes may be conditions appear to be rather frequent.

attached), separate products, push products (especially liq-

uids), gather data (when fitted with special electronic devices), B. Internal monitoring 2 pts

detect leaks, etc. A wide variety of special-purpose pigs in Inhibitor injection 2 pts

many shapes and configurations is possible. There is even a Operational measures 2 pts

bypass pig that is designed with a relief valve to clear debris Pigging 3 pts

from in front of the pig if the debris causes a high differential

pressure across the pig. Total 9 pts (out of IO pts max)

A regular program of running cleaning or displacement-type Points were deducted from each of two of the preventive

pigs to remove potentially corrosive materials is a proven effec- measures (inhibitor injection and operational measures)

tive method of reducing (but not eliminating) damage from because of known reliability problems with the actions. A

internal corrosion. The program should be designed to remove penalty for the offshore operational measures was actually

liquids or other materials before they can do appreciable dam- taken twice in this case, once in the product corrosivity and

age to the pipe wall. Monitoring of the materials displaced from once in the preventive actions.

the pipeline should include a search for corrosion products The total score for internal corrosion is then:

such as iron oxide in steel lines. This will help to assess the

extent of corrosion in the line. A+B = 5 + 9 = 14 pts

Pigging is partly an experience-driven technique. From a

wide selection of pig types, the knowledgeable operator must

choose an appropriate model, design the pigging protocol C. Subsurface corrosion (weighting: 70%)

including pig speed, distance, and driving force, and assess the

progress during the operation. The evaluator should be satisfied Subsurface Corrosion (70% of overall corrosion threat,

that the pigging operation is indeed beneficial and effective in 7Opts)

removing corrosive products from the line in a timely fashion.

Subsurface environment (20 pts)

Soil corrosivity (15 pts)

Example 4.5: Scoring internal corrosion Mechanical corrosion (5 pts)

Coating (25 pts)

A section of natural gas pipeline (steel) is being examined. Fitness (1 0 pts)

The line transports gas from offshore production wells. The gas Condition (15 pts)

is dried and treated (removal of sulfur) offshore, but the off- Cathodic protection (25 pts)

shore treating equipment malfunctions rather routinely. The Effectiveness (15 pts)

operator injects inhibitor to control corrosion from any off- Interference potential (10 pts)

shore liquids that escape the dehydration process. Recently, it AC related (2 pts)

was discovered that the inhibitor injector had failed for a period Shielding (1 pt)

of 2 weeks before the malfunction was corrected. The operator DC related (7 pts)

also runs pigs once per month to remove any free-standing liq- Telluric currents (1 pt)

uids in the pipeline. Corrosion probes provide continuous data DC rail (3 pts)

on the corrosion rate inside the line. Foreign lines (3 pts)

Figure4.4 Examples of pipeline pigs