Page 98 - Pipeline Risk Management Manual Ideas, Techniques, and Resources

P. 98

4/76 Corrosion Index

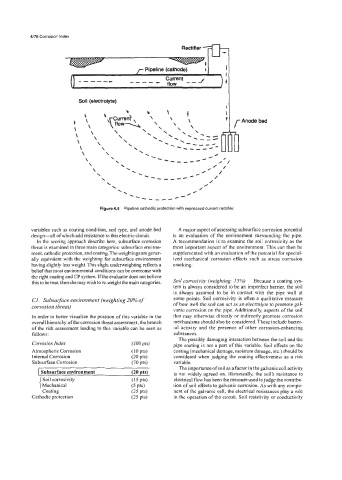

Rectifier

r Pipeline (cath

bed

Figure 4.6 Pipeline cathodic protection with impressed current rectifier

variables such as coating condition, soil type, and anode bed A major aspect of assessing subsurface corrosion potential

design-all of which add resistance to this electric circuit. is an evaluation of the environment surrounding the pipe.

In the scoring approach describe here, subsurface corrosion A recommendation is to examine the soil corrosivity as the

threat is examined in three main categories: subsurface envuon- most important aspect of the environment. This can then be

ment. cathodic protection, and coating. The weightings are gener- supplemented with an evaluation of the potential for special-

ally equivalent with the weighting for subsurface environment ized mechanical corrosion effects such as stress corrosion

having slightly less weight. This slight underweighting reflects a cracking.

belief that most environmental conditions can be overcome with

the right coating and CP system. If the evaluator does not believe

this to he true, then she may wish to re-weight the main categories. Soil corrosiviw (weighting: 15%) Because a coating sys-

tem is always considered to he an imperfect barrier, the soil

is always assumed to he in contact with the pipe wall at

C1. Subsurface environment (weighting 20% of some points. Soil corrosivity is often a qualitative measure

corrosion threat) of how well the soil can act as an electrolyte to promote gal-

vanic corrosion on the pipe. Additionally, aspects of the soil

In order to better visualize the position of this variable in the that may otherwise directly or indirectly promote corrosion

overall hierarchy of the corrosion threat assessmeb, the branch mechanisms should also be considered. These include bacter-

of the risk assessment leading to this variable can be seen as ial activity and the presence of other corrosion-enhancing

follows: substances.

The possibly damaging interaction between the soil and the

Corrosion Index pipe coating is not a part of this variable. Soil effects on the

Atmospheric Corrosion coating (mechanical damage, moisture damage, etc.) should he

Internal Corrosion considered when judging the coating effectiveness as a risk

Subsurface Corrosion variable.

The importance of soil as a factor in the galvanic cell activity

Subsurface environment (20 PtS) I is not widely agreed on. Historically, the soil's resistance to

electrical flow has been the measure used to judge the contribu-

Soil corrosivity

{ Mechanical (15 pts) tion of soil effects to galvanic corrosion. As with any compo-

(5 Pts)

Coating (25 PtS) nent of the galvanic cell, the electrical resistances play a role

Cathodic protection (25 pts) in the operation of the circuit. Soil resistivity or conductivity