Page 148 - Pipeline Rules of Thumb Handbook

P. 148

Hydrostatic Testing 135

86.6psig (200 feet ¥ 0.433 = 86.6psig). A test pressure equal

to 90% of SMYS is 1,404psig. Since the test site is lower

than the high end of the line, the 86.6psig is added to

1,404psig to obtain a test site pressure of 1,491psig. The pres-

sure at the end of the line will be 1,404psig which equates to

90% of SMYS. The pressure at the low point equates to 96%

of SMYS.

Now, let’s assume a line has a high point elevation of 1,100

feet, a low elevation point of 1,000 feet, and the elevation

at the test site is 1,050 feet. The test pressure at the high

point will need to be 1,404psig in order to meet the

90% of SMYS requirement. The pressure at the low point

will be 1,447psig, and the pressure at the test site will be

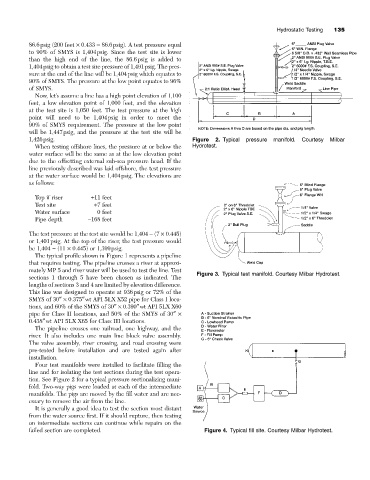

1,426psig. Figure 2. Typical pressure manifold. Courtesy Milbar

When testing offshore lines, the pressure at or below the Hydrotest.

water surface will be the same as at the low elevation point

due to the offsetting external sub-sea pressure head. If the

line previously described was laid offshore, the test pressure

at the water surface would be 1,404psig. The elevations are

as follows:

Top if riser +11 feet

Test site +7 feet

Water surface 0 feet

Pipe depth -168 feet

The test pressure at the test site would be 1,404 - (7 ¥ 0.445)

or 1,401psig. At the top of the riser, the test pressure would

be 1,404 - (11 ¥ 0.445) or 1,399psig.

The typical profile shown in Figure 1 represents a pipeline

that requires testing. The pipeline crosses a river at approxi-

mately MP 5 and river water will be used to test the line. Test

Figure 3. Typical test manifold. Courtesy Milbar Hydrotest.

sections 1 through 5 have been chosen as indicated. The

lengths of sections 3 and 4 are limited by elevation difference.

This line was designed to operate at 936psig or 72% of the

SMYS of 30≤¥ 0.375≤wt API 5LX X52 pipe for Class I loca-

tions, and 60% of the SMYS of 30≤¥ 0.390≤wt API 5LX X60

pipe for Class II locations, and 50% of the SMYS of 30≤¥

0.438≤wt API 5LX X65 for Class III locations.

The pipeline crosses one railroad, one highway, and the

river. It also includes one main line block valve assembly.

The valve assembly, river crossing, and road crossing were

pre-tested before installation and are tested again after

installation.

Four test manifolds were installed to facilitate filling the

line and for isolating the test sections during the test opera-

tion. See Figure 2 for a typical pressure sectionalizing mani-

fold. Two-way pigs were loaded at each of the intermediate

manifolds. The pigs are moved by the fill water and are nec-

essary to remove the air from the line.

It is generally a good idea to test the section most distant

from the water source first. If it should rupture, then testing

on intermediate sections can continue while repairs on the

failed section are completed. Figure 4. Typical fill site. Courtesy Milbar Hydrotest.