Page 150 - Pipeline Rules of Thumb Handbook

P. 150

Hydrostatic Testing 137

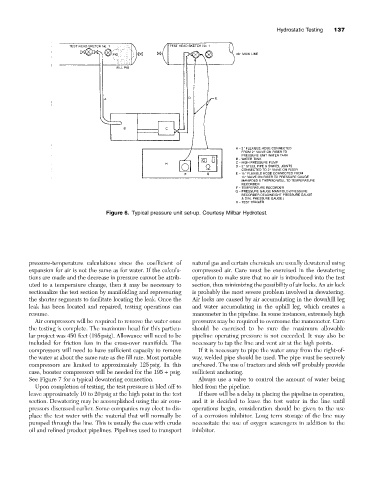

Figure 6. Typical pressure unit set-up. Courtesy Milbar Hydrotest.

pressure-temperature calculations since the coefficient of natural gas and certain chemicals are usually dewatered using

expansion for air is not the same as for water. If the calcula- compressed air. Care must be exercised in the dewatering

tions are made and the decrease in pressure cannot be attrib- operation to make sure that no air is introduced into the test

uted to a temperature change, then it may be necessary to section, thus minimizing the possibility of air locks. An air lock

sectionalize the test section by manifolding and repressuring is probably the most severe problem involved in dewatering.

the shorter segments to facilitate locating the leak. Once the Air locks are caused by air accumulating in the downhill leg

leak has been located and repaired, testing operations can and water accumulating in the uphill leg, which creates a

resume. manometer in the pipeline. In some instances, extremely high

Air compressors will be required to remove the water once pressures may be required to overcome the manometer. Care

the testing is complete. The maximum head for this particu- should be exercised to be sure the maximum allowable

lar project was 450 feet (195psig). Allowance will need to be pipeline operating pressure is not exceeded. It may also be

included for friction loss in the cross-over manifolds. The necessary to tap the line and vent air at the high points.

compressors will need to have sufficient capacity to remove If it is necessary to pipe the water away from the right-of-

the water at about the same rate as the fill rate. Most portable way, welded pipe should be used. The pipe must be securely

compressors are limited to approximately 125psig. In this anchored. The use of tractors and skids will probably provide

case, booster compressors will be needed for the 195 + psig. sufficient anchoring.

See Figure 7 for a typical dewatering connection. Always use a valve to control the amount of water being

Upon completion of testing, the test pressure is bled off to bled from the pipeline.

leave approximately 10 to 20psig at the high point in the test If there will be a delay in placing the pipeline in operation,

section. Dewatering may be accomplished using the air com- and it is decided to leave the test water in the line until

pressors discussed earlier. Some companies may elect to dis- operations begin, consideration should be given to the use

place the test water with the material that will normally be of a corrosion inhibitor. Long term storage of the line may

pumped through the line. This is usually the case with crude necessitate the use of oxygen scavengers in addition to the

oil and refined product pipelines. Pipelines used to transport inhibitor.