Page 274 - Pipelines and Risers

P. 274

Remaining Strength of Corroded Pipes 247

Available Information

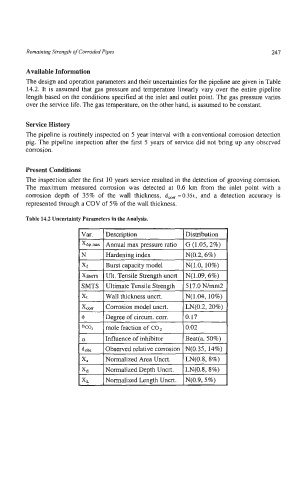

The design and operation parameters and their uncertainties for the pipeline are given in Table

14.2. It is assumed that gas pressure and temperature linearly vary over the entire pipeline

length based on the conditions specified at the inlet and outlet point. The gas pressure varies

over the service life. The gas temperature, on the other hand, is assumed to be constant.

Service History

The pipeline is routinely inspected on 5 year interval with a conventional corrosion detection

pig. The pipeline inspection after the first 5 years of service did not bring up any obscrved

corrosion.

Present Conditions

The inspection after the first 10 years service resulted in the detection of grooving corrosion.

The maximum measured Corrosion was detected at 0.6 km from the inlet point with a

corrosion depth of 35% of the wall thickness, d, =0.35t, and a detection accuracy is

represented through a COV of 5% of the wall thickness.

Table 14.2 Uncertainty Parameters in the Analysis.

I Var. I Description I Distribution 1

xA~.max Annual max pressure ratio G (1.05,2%)

N Hardening index N(0.2,6%)

Xf Burst capacity model N( 1 .O, 10%)

XSMTS Ut. Tensile Strength uncrt N(1.09,6%)

SMTS Ultimate Tensile Strength 517.0 N/mm2

Xt Wall thickness uncrt. N(1.04, 10%)

X, Corrosion model uncrt. LN(0.2,20%)

Q Degree of circum. con. 0.17

I "~02 1 mole fraction of co2 10.02 I

~~

a Influence of inhibitor Beat(a, 50%) -

dobs Observed relative corrosion N(0.35, 14%)

X, Normalized Area Uncrt. LN(0.8,8%)

xd Normalized Depth Uncrt. LN(0.8,8%)

XL Normalized Length Uncrt. N(0.9,5%)