Page 357 - Pipelines and Risers

P. 357

328 Chapter 18

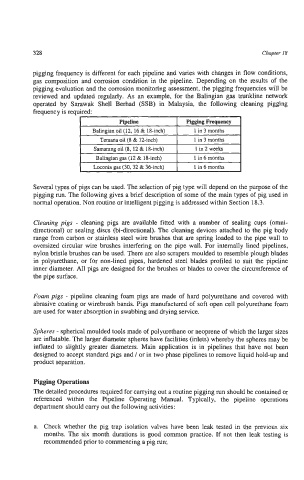

pigging frequency is different for each pipeline and varies with changes in flow conditions,

gas composition and corrosion condition in the pipeline. Depending on the results of the

pigging evaluation and the corrosion monitoring assessment, the pigging frequencies will be

reviewed and updated regularly. As an example, for the Balingian gas trunkline network

operated by Sarawak Shell Berhad (SSB) in Malaysia, the following cleaning pigging

frequency is required

Pipeline I Pigging Frequency

Balineian oil (12. 16 & Winch) 1 1 in 3 months

I Temana oil (8 & 12-inch) I 1 in 3 months I

~

Samarang oil (8, 12 & 18-inch) 1 in 2 weeks

Balingian gas (12 & 18-inch) 1 in 6 months

Loconia gas (30.32 & 36-inch) 1 in 6 months

Several types of pigs can be used. The selection of pig type will depend on the purpose of the

pigging run. The following gives a brief description of some of the main types of pig used in

normal operation. Non routine or intelligent pigging is addressed within Section 18.3.

Cleaning pigs - cleaning pigs are available fitted with a number of sealing cups (omni-

directional) or sealing discs (bi-directional). The cleaning devices attached to the pig body

range from carbon or stainless steel wire brushes that are spring loaded to the pipe wall to

oversized circular wire brushes interfering on the pipe wall. For internally lined pipelines,

nylon bristle brushes can be used. There are also scrapers moulded to resemble plough blades

in polyurethane, or for non-lined pipes, hardened steel blades profiled to suit the pipeline

inner diameter. All pigs are designed for the brushes or blades to cover the circumference of

the pipe surface.

Foam pigs - pipeline cleaning foam pigs are made of hard polyurethane and covered with

abrasive coating or wirebrush bands. Pigs manufactured of soft open cell polyurethane foam

are used for water absorption in swabbing and drying service.

Spheres - spherical moulded tools made of polyurethane or neoprene of which the larger sizes

are inflatable. The larger diameter spheres have facilities (inlets) whereby the spheres may be

inflated to slightly greater diameters. Main application is in pipelines that have not been

designed to accept standard pigs and / or in two phase pipelines to remove liquid hold-up and

product separation.

pigging Operations

The detailed procedures required for carrying out a routine pigging run should be contained or

referenced within the Pipeline Operating Manual. Typically, the pipeline operations

department should carry out the following activities:

a. Check whether the pig trap isolation valves have been leak tested in the previous six

months. The six month durations is good common practice. If not then leak testing is

recommended prior to commencing a pig run;