Page 376 - Pipelines and Risers

P. 376

Pipeline Inspeciion, Mainienance and Repair 341

STABILISATION MATTRESS

IN INSTALLED POSITION

LEADING MATTRESS

EDGES SCOURED INTO

THE SEAEEO

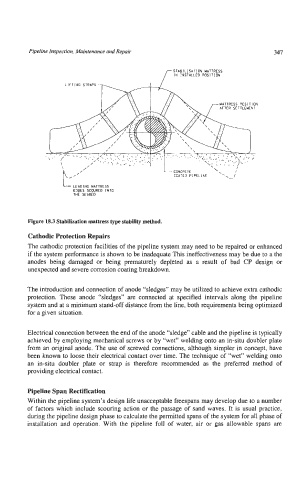

Figure 18.3 Stabilization mattress type stability method.

Cathodic Protection Repairs

The cathodic protection facilities of the pipeline system may need to be repaired or enhanced

if the system performance is shown to be inadequate This ineffectiveness may be due to a the

anodes being damaged or being prematurely depleted as a result of bad CP design or

unexpected and severe corrosion coating breakdown.

The introduction and connection of anode “sledges” may be utilized to achieve extra cathodic

protection. These anode “sledges” are connected at specified intervals along the pipeline

system and at a minimum stand-off distance from the line, both requirements being optimized

for a given situation.

Electrical connection between the end of the anode “sledge” cable and the pipeline is typically

achieved by employing mechanical screws or by “wet” welding onto an in-situ doubler plate

from an original anode. The use of screwed connections, although simpler in concept, have

been known to loose their electrical contact over time. The technique of “wet” welding onto

an in-situ doubler plate or strap is therefore recommended as the preferred method of

providing electrical contact.

Pipeline Span Rectification

Within the pipeline system’s design life unacceptable freespans may develop due to a number

of factors which include scouring action or the passage of sand waves. It is usual practice,

during the pipeline design phase to calculate the permitted spans of the system for all phase of

installation and operation. With the pipeline full of water, air or gas allowable spans are