Page 387 - Pipelines and Risers

P. 387

356 Chuprer 19

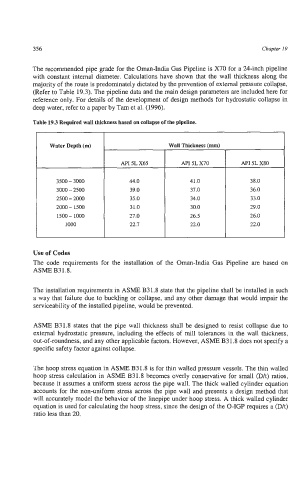

The recommended pipe grade for the Oman-India Gas Pipeline is X70 for a 24-inch pipeline

with constant internal diameter. Calculations have shown that the wall thickness along the

majority of the route is predominately dictated by the prevention of external pressure collapse,

(Refer to Table 19.3). The pipeline data and the main design parameters are included here for

reference only. For details of the development of design methods for hydrostatic collapse in

deep water, refer to a paper by Tam et al. (1996).

Table 19.3 Required wall thickness based on collapse of the pipeline.

Water Depth (m) Wall Thickness (mm)

API 5L X65 AF'I 5L X70 API 5L X80

3500 - 3000 44.0 41 .O 38.0

3000 - 2500 39.0 37.0 36.0

2500 - 2000 35.0 34.0 33.0

2000 - 1500 31.0 30.0 29.0

1500 - 1000 27.0 26.5 26.0

1000 22.1 22.0 22.0

Use of Codes

The code requirements for the installation of the Oman-India Gas Pipeline are based on

ASMEB31.8.

The installation requirements in ASME B31.8 state that the pipeline shall be installed in such

a way that failure due to buckling or collapse, and any other damage that would impair the

serviceability of the installed pipeline, would be prevented.

ASME B31.8 states that the pipe wall thickness shall be designed to resist collapse due to

external hydrostatic pressure, including the effects of mill tolerances in the wall thickness,

out-of-roundness, and any other applicable factors. However, ASME B31.8 does not specify a

specific safety factor against collapse.

The hoop stress equation in ASME B31.8 is for thin walled pressure vessels. The thin walled

hoop stress calculation in ASME B31.8 becomes overly conservative for small @/t) ratios,

because it assumes a uniform stress across the pipe wall. The thick walled cylinder equation

accounts for the non-uniform stress across the pipe wall and presents a design method that

will accurately model the behavior of the linepipe under hoop stress. A thick walled cylinder

equation is used for calculating the hoop stress, since the design of the 0-IGP requires a @/t)

ratio less than 20.