Page 394 - Pipelines and Risers

P. 394

362 Chapter 19

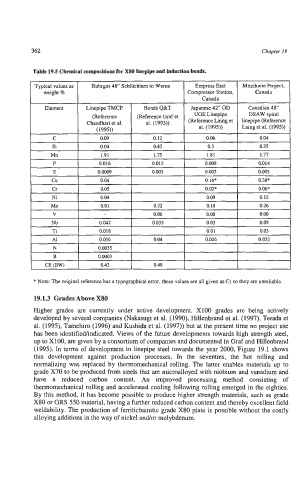

Typical values as Ruhrgas 48” Schliichtern to Werne Empress East Mitzihwin Project,

weight ’70 Compressor Station, Canada

Canada

Element Linepipe TMCP Bends Q&T Japanese 42” OD Canadian 48”

(Reference (Reference Graf et Linepipe DSAW spiral

Chaudhari et al. al, (1993)) (Reference Laing et linepipe (Reference

al. (1995)) Laing et al. (1995))

(1995))

C 0.09 0.12 0.06 0.04

Si 0.04 0.45 0.3 0.35

Mn 1.91 1.75 1.81 1.77

P 0.016 0.015 0.008 0.014

S 0.0009 0.003 0.003 0.005

cu 0.04 0.16* 0.38*

Cr 0.05 O.W* 0.06*

Ni 0.04 0.09 0.15

~ ~

Mo 0.01 0.22 0.18 0.26

V 0.06 0.08 0.00

Nb 0.042 0.035 0.03 0.09

Ti 0.018 0.01 0.03

AI 0.036 0.04 0.026 0.032

N 0.0035

B 0.0003

CE (IN) 0.43 0.48

* Note: The original reference has a typographical error, these values are all given as Cr so they are unreliable.

19.1.3 Grades Above XSO

Higher grades are currently under active development. XlOO grades are being actively

developed by several companies (Nakasugi et al. (1990), Hillenbrand et al. (1997), Terada et

al. (1995), Tamehiro (1996) and Kushida et al. (1997)) but at the present time no project use

has been identifiedlindicated. Views of the future developments towards high strength steel,

up to XIOO, are given by a consortium of companies and documented in Graf and Hillenbrand

(1995). In terms of development in linepipe steel towards the year 2000, Figure 19.1 shows

this development against production processes. In the seventies, the hot rolling and

normalizing was replaced by thermomechanical rolling. The latter enables materials up to

grade X70 to be produced from steels that are microalloyed with niobium and vanadium and

have a reduced carbon content. An improved processing method consisting of

thermomechanical rolling and accelerated cooling following rolling emerged in the eighties.

By this method, it has become possible to produce higher strength materials, such as grade

X80 or GRS 550 material, having a further reduced carbon content and thereby excellent field

weldability. The production of ferriticbainitic grade X80 plate is possible without the costly

alloying additions in the way of nickel andor molybdenum.