Page 441 - Pipelines and Risers

P. 441

408 Chapter 21

Comparison is performed for:

The moment for failure based on the Hauch & Bai (1999).

Allowable moments (including utilization factors) for each of the three approaches. For

the MI approach, based on allowable stresses, FEA analysis is performed to quantify the

equivalent moments for the allowable stress limit. The utilization factors used for each

approach are summarized in Table 21.7.

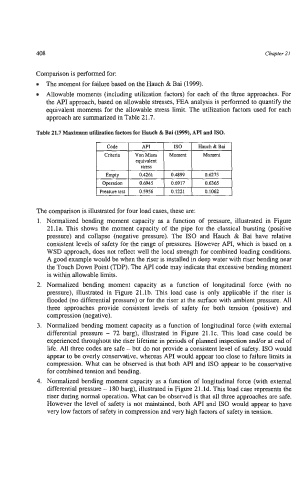

Table 21.7 Maxiinnun utilization factors for Hauch & Bai (1999), API and ISO.

I Code 1 API 1 IS0 I Hauch&Bai 1

Moment

equivalent

0.4261 0.4899 0.6275

The comparison is illustrated for four load cases, these are:

1. Normalized bending moment capacity as a function of pressure, illustrated in Figure

21.la. This shows the moment capacity of the pipe for the classical bursting (positive

pressure) and collapse (negative pressure). The IS0 and Hauch & Bai have relative

consistent levels of safety for the range of pressures. However MI, which is based on a

WSD approach, does not reflect well the local strength for combined loading conditions.

A good example would be when the riser is installed in deep water with riser bending near

the Touch Down Point (TDP). The API code may indicate that excessive bending moment

is within allowable limits.

2. Normalized bending moment capacity as a function of longitudinal force (with no

pressure), illustrated in Figure 21.lb. This load case is only applicable if the riser is

flooded (no differential pressure) or for the riser at the surface with ambient pressure. All

three approaches provide consistent levels of safety for both tension (positive) and

compression (negative).

3. Normalized bending moment capacity as a function of longitudinal force (with external

differential pressure - 72 barg), illustrated in Figure 21.1~. This load case could be

experienced throughout the riser lifetime in periods of planned inspection andor at end of

life. All three codes are safe - but do not provide a consistent level of safety. IS0 would

appear to be overly conservative, whereas API would appear too close to failure limits in

compression. What can be observed is that both API and IS0 appear to be conservative

for combined tension and bending.

4. Normalized bending moment capacity as a function of longitudinal force (with external

differential pressure - 180 barg), illustrated in Figure 21.ld. This load case represents the

riser during normal operation. What can be observed is that all three approaches are safe.

However the level of safety is not maintained, both API and IS0 would appear to have

very low factors of safety in compression and very high factors of safety in tension.