Page 31 - Piston Engine-Based Power Plants

P. 31

Types of Reciprocating Engine 23

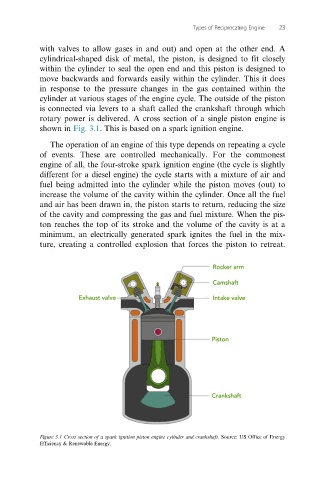

with valves to allow gases in and out) and open at the other end. A

cylindrical-shaped disk of metal, the piston, is designed to fit closely

within the cylinder to seal the open end and this piston is designed to

move backwards and forwards easily within the cylinder. This it does

in response to the pressure changes in the gas contained within the

cylinder at various stages of the engine cycle. The outside of the piston

is connected via levers to a shaft called the crankshaft through which

rotary power is delivered. A cross section of a single piston engine is

shown in Fig. 3.1. This is based on a spark ignition engine.

The operation of an engine of this type depends on repeating a cycle

of events. These are controlled mechanically. For the commonest

engine of all, the four-stroke spark ignition engine (the cycle is slightly

different for a diesel engine) the cycle starts with a mixture of air and

fuel being admitted into the cylinder while the piston moves (out) to

increase the volume of the cavity within the cylinder. Once all the fuel

and air has been drawn in, the piston starts to return, reducing the size

of the cavity and compressing the gas and fuel mixture. When the pis-

ton reaches the top of its stroke and the volume of the cavity is at a

minimum, an electrically generated spark ignites the fuel in the mix-

ture, creating a controlled explosion that forces the piston to retreat.

Figure 3.1 Cross section of a spark ignition piston engine cylinder and crankshaft. Source: US Office of Energy

Efficiency & Renewable Energy.