Page 32 - Piston Engine-Based Power Plants

P. 32

24 Piston Engine-Based Power Plants

This is the power stroke the drives the engine. The movement of the

piston away from the cylinder head is eventually arrested mechanically

and the piston begins to return once more to the top of the cylinder.

As it does the combustion gases are expelled from the cylinder. As the

piston reaches the top again, and all the gases have been expelled, the

cycle repeats with a fresh charge of fuel and air being admitted.

In order for gases to be admitted and removed from the cylinder

during this cycle there are valves fitted to the upper part of the cylinder

chamber. These are controlled mechanically via a shaft (the camshaft)

and levers (the rocker arms) that synchronise their movements to the

movement of the piston within the cylinder. One valve, or a set of

valves, is used to admit fuel and air into the cylinder while another

valve or set allows these same gases to be expelled once combustion

has taken place.

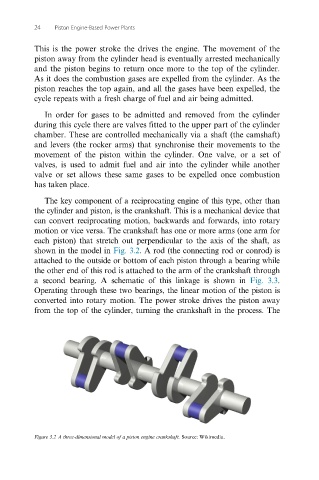

The key component of a reciprocating engine of this type, other than

the cylinder and piston, is the crankshaft. This is a mechanical device that

can convert reciprocating motion, backwards and forwards, into rotary

motion or vice versa. The crankshaft has one or more arms (one arm for

each piston) that stretch out perpendicular to the axis of the shaft, as

shown in the model in Fig. 3.2. A rod (the connecting rod or conrod) is

attached to the outside or bottom of each piston through a bearing while

the other end of this rod is attached to the arm of the crankshaft through

a second bearing. A schematic of this linkage is shown in Fig. 3.3.

Operating through these two bearings, the linear motion of the piston is

converted into rotary motion. The power stroke drives the piston away

from the top of the cylinder, turning the crankshaft in the process. The

Figure 3.2 A three-dimensional model of a piston engine crankshaft. Source: Wikimedia.