Page 103 - Plant design and economics for chemical engineers

P. 103

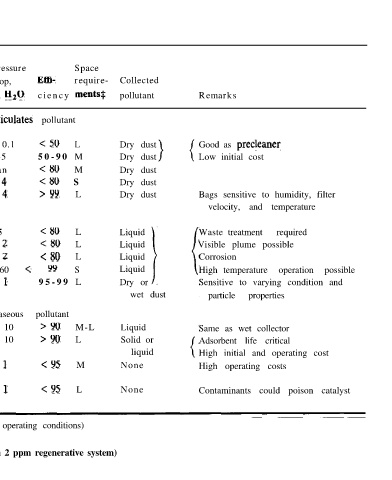

TABLE 8

3 Air pollution control equipment characteristics

Optimum? Optimum

size concen- Tempera- Pressure Space

Control particle, tration, ture limi- drop, Effi- require- Collected

equipment microns grains / ft3 tations, “F in. H,O ciency ments$ pollutant Remarks

Particulates pollutant

Mechanical collectors

Settling chamber > 50 >5 < 0.1 <50 L Dry dust Good as precleaner

Cyclone 5-25 >1 1-5 5 0 - 9 0 M Dry dust Low initial cost

Dynamic precipitator > 10 >l Fan <80 M Dry dust

Impingement separator > 10 >l <4 <SO S Dry dust

Bag filter <I > 0.1 >4 >99 L Dry dust Bags sensitive to humidity, filter

velocity, and temperature

Wet collector

Spray tower 25 >1 40-700 0.5 <80 L Liquid Waste treatment required

Cyclone >5 >l 40-700 >2 <80 L Liquid Visible plume possible

Impingement >5 >1 40-700 >2 <80 L Liquid Corrosion

Venturi <l > 0.1 40-700 1-60 < 99 S Liquid High temperature operation possible

Electrostatic precipitator <I > 0.1 850 <l 9 5 - 9 9 L Dry or 1 Sensitive to varying condition and

wet dust particle properties

Gaseous pollutant

Gas scrubber > 1% 40-100 < 10 >90 M-L Liquid Same as wet collector

Gas adsorber 8 40-100 < 10 >90 L Solid or Adsorbent life critical

liquid High initial and operating cost

Direct incinerator Combustible 2000 <I <95 M None High operating costs

vatxxs

Catalytic combustion >1 <95 L None Contaminants could poison catalyst

vapors

t Minimum particle size (collected at approximately 90% efficiency under usual operating conditions)

$ Space requirements: S = small, M = moderate, L = large

8 Adsorber (concentrations less than 2 ppm non-regenerative system; greater than 2 ppm regenerative system)