Page 98 - Plant design and economics for chemical engineers

P. 98

76 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

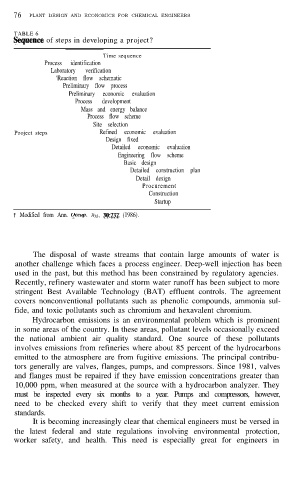

TABLE 6

!hquence of steps in developing a project?

Time sequence

Process identification

Laboratory verification

‘Reaction flow schematic

Preliminary flow process

Preliminary economic evaluation

Process development

Mass and energy balance

Process flow scheme

Site selection

Project steps Refined economic evaluation

Design fixed

Detailed economic evaluation

Engineering flow scheme

Basic design

Detailed construction plan

Detail design

Procurement

Construction

Startup

t Modified from Ann. Occup. Hyg., 30~232 (1986).

The disposal of waste streams that contain large amounts of water is

another challenge which faces a process engineer. Deep-well injection has been

used in the past, but this method has been constrained by regulatory agencies.

Recently, refinery wastewater and storm water runoff has been subject to more

stringent Best Available Technology (BAT) effluent controls. The agreement

covers nonconventional pollutants such as phenolic compounds, ammonia sul-

fide, and toxic pollutants such as chromium and hexavalent chromium.

Hydrocarbon emissions is an environmental problem which is prominent

in some areas of the country. In these areas, pollutant levels occasionally exceed

the national ambient air quality standard. One source of these pollutants

involves emissions from refineries where about 85 percent of the hydrocarbons

emitted to the atmosphere are from fugitive emissions. The principal contribu-

tors generally are valves, flanges, pumps, and compressors. Since 1981, valves

and flanges must be repaired if they have emission concentrations greater than

10,000 ppm, when measured at the source with a hydrocarbon analyzer. They

must be inspected every six months to a year. Pumps and compressors, however,

need to be checked every shift to verify that they meet current emission

standards.

It is becoming increasingly clear that chemical engineers must be versed in

the latest federal and state regulations involving environmental protection,

worker safety, and health. This need is especially great for engineers in