Page 95 - Plant design and economics for chemical engineers

P. 95

GENERAL DESIGN CONSIDERATIONS 73

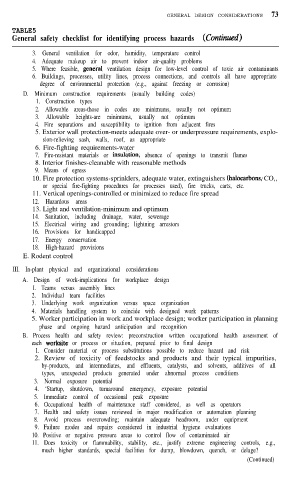

TABLE5

General safety checklist for identifying process hazards (Continued)

3. General ventilation for odor, humidity, temperature control

4. Adequate makeup air to prevent indoor air-quality problems

5. Where feasible, geneial ventilation design for low-level control of toxic air contaminants

6. Buildings, processes, utility lines, process connections, and controls all have appropriate

degree of environmental protection (e.g., against freezing or corrosion)

D. Minimum construction requirements (usually building codes)

1. Construction types

2. Allowable areas-those in codes are minimums, usually not optimum

3. Allowable heights-are minimums, usually not optimum

4. Fire separations and susceptibility to ignition from adjacent fires

5. Exterior wall protection-meets adequate over- or underpressure requirements, explo-

sion-relieving sash, walls, roof, as appropriate

6. Fire-fighting requirements-water

7. Fire-resistant materials or insul&on, absence of openings to transmit flames

8. Interior finishes-cleanable with reasonable methods

9. Means of egress

10. Fire protection systems-sprinklers, adequate water, extinguishers (halocarbons, CO,,

or special fire-fighting procedures for processes used), fire trucks, carts, etc.

11. Vertical openings-controlled or minimized to reduce fire spread

12. Hazardous areas

13. Light and ventilation-minimum and optimum

14. Sanitation, including drainage, water, sewerage

15. Electrical wiring and grounding; lightning arrestors

16. Provisions for handicapped

17. Energy conservation

18. High-hazard provisions

E. Rodent control

III. In-plant physical and organizational considerations

A. Design of work-implications for workplace design

1. Teams versus assembly lines

2. Individual team facilities

3. Underlying work organization versus space organization

4. Materials handling system to coincide with designed work patterns

5. Worker participation in work and workplace design; worker participation in planning

phase and ongoing hazard anticipation and recognition

B. Process health and safety review: preconstruction written occupational health assessment of

each worksite or process or situation, prepared prior to final design

1. Consider material or process substitutions possible to reduce hazard and risk

2. Review of toxicity of feedstocks and products and their typical impurities,

by-products, and intermediates, and effluents, catalysts, and solvents, additives of all

types, unexpected products generated under abnormal process conditions

3. Normal exposure potential

4. ‘Startup, shutdown, turnaround emergency, exposure potential

5. Immediate control of occasional peak exposure

6. Occupational health of maintenance staff considered, as well as operators

7. Health and safety issues reviewed in major modification or automation planning

8. Avoid process overcrowding; maintain adequate headroom, under equipment

9. Failure modes and repairs considered in industrial hygiene evaluations

10. Positive or negative pressure areas to control flow of contaminated air

11. Does toxicity or flammability, stability, etc., justify extreme engineering controls, e.g.,

much higher standards, special facilities for dump, blowdown, quench, or deluge?

(Continued)