Page 96 - Plant design and economics for chemical engineers

P. 96

74 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

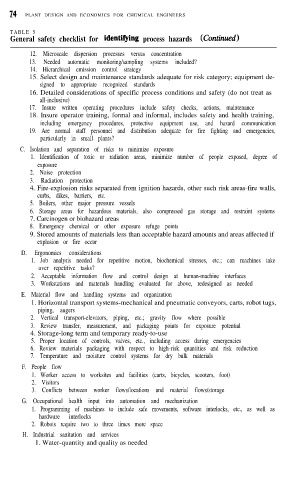

TABLE 5

General safety checklist for identifying process hazards (Continued)

12. Microscale dispersion processes versus concentration

13. Needed automatic monitoring/sampling systems included?

14. Hierarchical emission control strategy

15. Select design and maintenance standards adequate for risk category; equipment de-

signed to appropriate recognized standards

16. Detailed considerations of specific process conditions and safety (do not treat as

all-inclusive)

17. Insure written operating procedures include safety checks, actions, maintenance

18. Insure operator training, formal and informal, includes safety and health training,

including emergency procedures, protective equipment use, and hazard communication

19. Are normal staff personnel and distribution adequate for fire fighting and emergencies,

particularly in small plants?

C. Isolation and separation of risks to minimize exposure

1. Identification of toxic or radiation areas, minimize number of people exposed, degree of

exposure

2. Noise protection

3. Radiation protection

4. Fire-explosion risks separated from ignition hazards, other such risk areas-fire walls,

curbs, dikes, barriers, etc.

5. Boilers, other major pressure vessels

6. Storage areas for hazardous materials, also compressed gas storage and restraint systems

7. Carcinogen or biohazard areas

8. Emergency chemical or other exposure refuge points

9. Stored amounts of materials less than acceptable hazard amounts and areas affected if

explosion or fire occur

D. Ergonomics considerations

1. Job analysis needed for repetitive motion, biochemical stresses, etc.; can machines take

over repetitive tasks?

2. Acceptable information flow and control design at human-machine interfaces

3. Workstations and materials handling evaluated for above, redesigned as needed

E. Material flow and handling systems and organization

1. Horizontal transport systems-mechanical and pneumatic conveyors, carts, robot tugs,

piping, augers

2. Vertical transport-elevators, piping, etc.; gravity flow where possible

3. Review transfer, measurement, and packaging points for exposure potential

4. Storage-long term and temporary ready-to-use

5. Proper location of controls, valves, etc., including access during emergencies

6. Review materials packaging with respect to high-risk quantities and risk reduction

7. Temperature and moisture control systems for dry bulk materials

F. People flow

1. Worker access to worksites and facilities (carts, bicycles, scooters, foot)

2. Visitors

3. Conflicts between worker flows/locations and material flows/storage

G. Occupational health input into automation and mechanization

1. Programming of machines to include safe movements, software interlocks, etc., as well as

hardware interlocks

2. Robots require two to three times more space

H. Industrial sanitation and services

1. Water-quantity and quality as needed