Page 94 - Plant design and economics for chemical engineers

P. 94

72 PLANT DESIGN AND ECONOMICS FOR CHEMICAL ENGINEERS

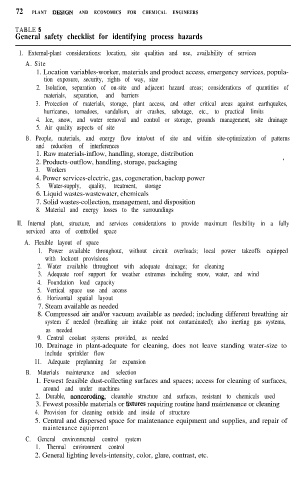

TABLE 5

General safety checklist for identifying process hazards

1. External-plant considerations: location, site qualities and use, availability of services

A. Site

1. Location variables-worker, materials and product access, emergency services, popula-

tion exposure, security, rights of way, size

2. Isolation, separation of on-site and adjacent hazard areas; considerations of quantities of

materials, separation, and barriers

3. Protection of materials, storage, plant access, and other critical areas against earthquakes,

hurricanes, tornadoes, vandalism, air crashes, sabotage, etc., to practical limits

4. Ice, snow, and water removal and control or storage, grounds management, site drainage

5. Air quality aspects of site

B. People, materials, and energy flow into/out of site and within site-optimization of patterns

and reduction of interferences

1. Raw materials-inflow, handling, storage, distribution ,

2. Products-outflow, handling, storage, packaging

3. Workers

4. Power services-electric, gas, cogeneration, backup power

5. Water-supply, quality, treatment, storage

6. Liquid wastes-wastewater, chemicals

7. Solid wastes-collection, management, and disposition

8. Material and energy losses to the surroundings

II. Internal plant, structure, and services considerations to provide maximum flexibility in a fully

serviced area of controlled space

A. Flexible layout of space

1. Power available throughout, without circuit overloads; local power takeoffs equipped

with lockout provisions

2. Water available throughout with adequate drainage; for cleaning

3. Adequate roof support for weather extremes including snow, water, and wind

4. Foundation load capacity

5. Vertical space use and access

6. Horizontal spatial layout

7. Steam available as needed

8. Compressed air and/or vacuum available as needed; including different breathing air

system if needed (breathing air intake point not contaminated); also inerting gas systems,

as needed

9. Central coolant systems provided, as needed

10. Drainage in plant-adequate for cleaning, does not leave standing water-size to

include sprinkler flow

11. Adequate preplanning for expansion

B. Materials maintenance and selection

1. Fewest feasible dust-collecting surfaces and spaces; access for cleaning of surfaces,

around and under machines

2. Durable, noncoroding, cleanable structure and surfaces, resistant to chemicals used

3. Fewest possible materials or fixtures requiring routine hand maintenance or cleaning

4. Provision for cleaning outside and inside of structure

5. Central and dispersed space for maintenance equipment and supplies, and repair of

maintenance equipment

C. General environmental control system

1. Thermal environment control

2. General lighting levels-intensity, color, glare, contrast, etc.