Page 185 - Plant design and economics for chemical engineers

P. 185

COST ESTIMATION 159

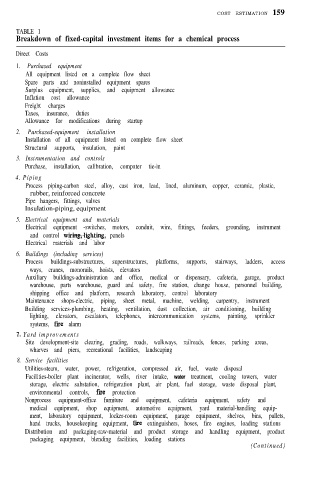

TABLE 1

Breakdown of fixed-capital investment items for a chemical process

Direct Costs

1. Purchased equipment

All equipment listed on a complete flow sheet

Spare parts and noninstalled equipment spares

Surplus equipment, supplies, and equipment allowance

Inflation cost allowance

Freight charges

Taxes, insurance, duties

Allowance for modifications during startup

2. Purchased-equipment installation

Installation of all equipment listed on complete flow sheet

Structural supports, insulation, paint

3. Instrumentation and controls

Purchase, installation, calibration, computer tie-in

4. Piping

Process piping-carbon steel, alloy, cast iron, lead, lined, aluminum, copper, ceramic, plastic,

rubber, reinforced concrete

Pipe hangers, fittings, valves

Insulation-piping, equipment

5. Electrical equipment and materials

Electrical equipment -switches, motors, conduit, wire, fittings, feeders, grounding, instrument

and control wiring$ghting, panels

Electrical materials and labor

6. Buildings (including services)

Process buildings-substructures, superstructures, platforms, supports, stairways, ladders, access

ways, cranes, monorails, hoists, elevators

Auxiliary buildings-administration and office, medical or dispensary, cafeteria, garage, product

warehouse, parts warehouse, guard and safety, fire station, change house, personnel building,

shipping office and platform, research laboratory, control laboratory

Maintenance shops-electric, piping, sheet metal, machine, welding, carpentry, instrument

Building services-plumbing, heating, ventilation, dust collection, air conditioning, building

lighting, elevators, escalators, telephones, intercommunication systems, painting, sprinkler

systems, file alarm

I. Yard improvements

Site development-site clearing, grading, roads, walkways, railroads, fences, parking areas,

wharves and piers, recreational facilities, landscaping

8. Service facilities

Utilities-steam, water, power, refrigeration, compressed air, fuel, waste disposal

Facilities-boiler plant incinerator, wells, river intake, water treatment, cooling towers, water

storage, electric substation, refrigeration plant, air plant, fuel storage, waste disposal plant,

environmental controls, fine protection

Nonprocess equipment-office furniture and equipment, cafeteria equipment, safety and

medical equipment, shop equipment, automotive equipment, yard material-handling equip-

ment, laboratory equipment, locker-room equipment, garage equipment, shelves, bins, pallets,

hand trucks, housekeeping equipment, fue extinguishers, hoses, fire engines, loading stations

Distribution and packaging-raw-material and product storage and handling equipment, product

packaging equipment, blending facilities, loading stations

(Continued)