Page 81 - Plant design and economics for chemical engineers

P. 81

GENERAL DESIGN CONSIDERATIONS 63

Part of-qualitative decrease (e.g., only one of two components in mix-

ture)

Reverse-opposite (e.g., backflow)

Other than-no part of the intent is achieved and something completely

different occurs (e.g., flow of wrong material)

These guide words are applied to flow, temperature, pressure, liquid level,

composition, and any other variable affecting the process.

The consequences of these deviations on the process are then assessed,

and the measures needed to detect and correct the deviations are established.

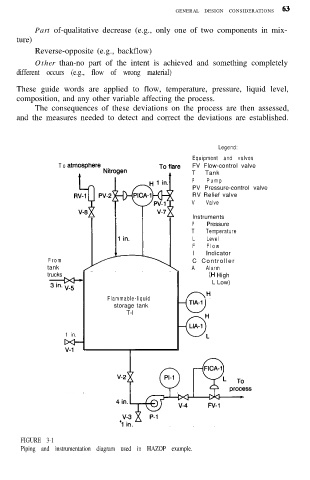

Legend:

Equipment and valves

T o FV Flow-control valve

T Tank

P P u m p

PV Pressure-control valve

RV Relief valve

V Valve

Instruments

P Pressure

T Temperature

L Level

F F l o w

I Indicator

F r o m C Controller

tank A Alarm

trucks (H High

L Low)

nH

Flammable-liquid

storage tank

T-l

1 in.

FIGURE 3-1

Piping and instrumentation diagram used in HAZOP example.