Page 180 - Plastics Engineering

P. 180

Mechanical Behaviour of Plastics 163

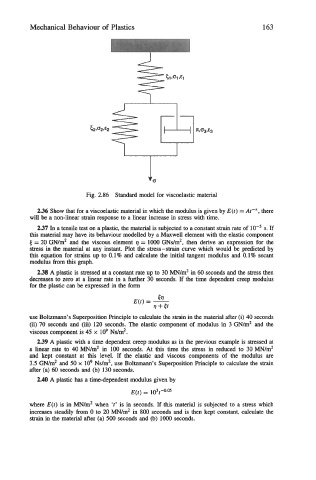

Fig. 2.86 Standard model for viscoelastic material

2.36 Show that for a viscoelastic material in which the modulus is given by E(t) = At-”, there

will be a non-linear strain response to a linear increase in stress with time.

2.37 In a tensile test on a plastic, the material is subjected to a constant strain rate of lo-’ s. If

this material may have its behaviour modelled by a Maxwell element with the elastic component

6 = 20 GN/m’ and the viscous element q = loo0 GNSlm’, then derive an expression for the

stress in the material at any instant. Plot the stress-strain curve which would be predicted by

this equation for strains up to 0.1% and calculate the initial tangent modulus and 0.1% secant

modulus from this graph.

2.38 A plastic is stressed at a constant rate up to 30 MN/m2 in 60 seconds and the stress then

decreases to zero at a linear rate in a further 30 seconds. If the time dependent creep modulus

for the plastic can be expressed in the form

h

E(t) = -

o+B

use Boltzmann’s Superposition Principle to calculate the strain in the material after (i) 40 seconds

(ii) 70 seconds and (iii) 120 seconds. The elastic component of modulus in 3 GN/m’ and the

viscous component is 45 x lo9 Nslm’.

2.39 A plastic with a time dependent creep modulus as in the previous example is stressed at

a linear rate to 40 MN/m2 in 100 seconds. At this time the stress in reduced to 30 MN/m’

and kept constant at this level. If the elastic and viscous components of the modulus are

3.5 GN/mz and 50 x lo9 NSlm’, use Boltzmann’s Superposition Principle to calculate the strain

after (a) 60 seconds and (b) 130 seconds.

2.40 A plastic has a time-dependent modulus given by

where E(t) is in MN/m2 when ‘t’ is in seconds. If this material is subjected to a stress which

increases steadily from 0 to 20 MN/mz in 800 seconds and is then kept constant, calculate the

strain in the material after (a) 500 seconds and (b) loo0 seconds.