Page 179 - Plastics Engineering

P. 179

162 Mechanical Behaviow of Plastics

2.26 If the stress in the composite beam in the previous question is not to exceed 7 MN/mz

estimate the maximum uniformly distributed load which it could carry over its whole length.

Calculate also the central deflection after 1 week under this load. The bending moment at the

centre of the beam is WL/24.

2.27 A rectangular section beam of solid polypropylene is 12 mm wide, 8 mm deep and

300 mm long. If a foamed core polypropylene beam, with a 2 mm solid skin on the upper

and lower surfaces only, is to be made the same width, length and weight estimate the depth

of the composite beam and state the ratio of the stiffness of the two beams. (p = 909 kg/m3,

p = 500 kg/m3).

2.28 Compare the flexural stiffness to weight ratios for the following three plastic beams. (a) a

solid beam of depth 12 mm, (b) a beam of foamed material 12 mm thick and (c) a composite

beam consisting of an 8 mm thick foamed core sandwiched between two solid skin layers 2 mm

thick. The ratio of densities of the solid and foamed material is 1.5. (hint: consider unit width

and unit length of beam).

2.29 For a sandwich beam with solid skins and a foamed core, show that (a) the weight of the

core should be twice the weight of the skin if the beam is to be designed for maximum stiffness

at minimum overall weight and (b) the weight of the core should equal the weight of the skin if

the beam is to be designed to provide maximum strength for minimum weight.

2.30 The viscoelastic behaviour of a certain plastic is to be represented by spring and dashpot

elements having constants of 2 GN/m2 and 90 GNs/m2 respectively. If a stress of 12 MN/mZ is

applied for 100 seconds and then completely removed, compare the values of strain predicted by

the Maxwell and Kelvin-Voigt models after (a) 50 seconds (b) 150 seconds.

2.31 Maxwell and Kelvin-Voigt models are to be set up to simulate the creep behaviour

of a plastic. The elastic and viscous constants for the Kelvin-Voigt models are 2 GN/m2 and

100 GNs/m2 respectively and the viscous constant for the Maxwell model is 200 GNs/m2. Esti-

mate a suitable value for the elastic constant for the Maxwell model if both models are to predict

the same creep strain after 50 seconds.

2.32 During a test on a polymer which is to have its viscoelastic behaviour described by the

Kelvin model the following creep data was obtained when a stress of 2 MN/m2 was applied to it.

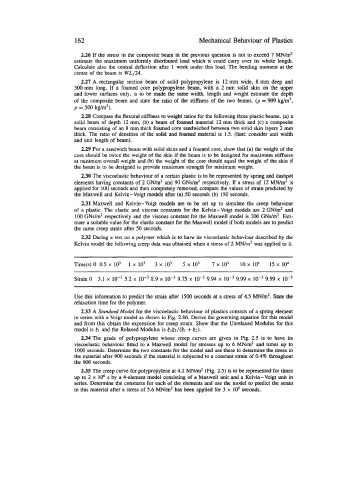

Time(s) 0 0.5 x lo3 1 x IO3 3 x lo3 5 x IO3 7 x lo3 10 x 104 15 x 104

Strain o 3.1 x 5.2 x 8.9 x 10-3 9.75 x 10-~ 9.94 x 9.99 x 10-~ 9.99 x 10-~

Use this information to predict the strain after 1500 seconds at a stress of 4.5 MN/m2. State the

relaxation time for the polymer.

2.33 A Standard Model for the viscoelastic behaviour of plastics consists of a spring element

in series with a Voigt model as shown in Fig. 2.86. Derive the governing equation for this model

and from this obtain the expression for creep strain. Show that the Unrelaxed Modulus for this

model is .$I and the Relaxed Modulus is .$l.$z/(e! + 62).

2.34 The grade of polypropylene whose creep curves are given in Fig. 2.5 is to have its

viscoelastic behaviour fitted to a Maxwell model for stresses up to 6 MN/m* and times up to

lo00 seconds. Determine the two constants for the model and use these to determine the stress in

the material after 900 seconds if the material is subjected to a constant strain of 0.446 throughout

the 900 seconds.

2.35 The creep curve for polypropylene at 4.2 htN/m2 (Fig. 2.5) is to be represented for times

up to 2 x IO6 s by a 4-element model consisting of a Maxwell unit and a Kelvin-Voigt unit in

series. Determine the constants for each of the elements and use the model to predict the strain

in this material after a stress of 5.6 MN/m2 has been applied for 3 x Id seconds.